-

-

Notifications

You must be signed in to change notification settings - Fork 500

New issue

Have a question about this project? Sign up for a free GitHub account to open an issue and contact its maintainers and the community.

By clicking “Sign up for GitHub”, you agree to our terms of service and privacy statement. We’ll occasionally send you account related emails.

Already on GitHub? Sign in to your account

How to connect laser module to cnc sheild v3.0 #368

Comments

|

|

If it's a Protoneer Shield look here: Also, what version of GRBL are you running? V3 boards are only compatible with GRBL 0.8 |

|

Im using v3.0 cnc sheild and grbl 1.1f (latest version) . Currently i made a 4xidraw corexy pen plotter and it's working well. So i need to improve it adding a laser module. |

|

Do you have an Arduino Uno. If so then I think you can connect the yellow PWM wire from the Laser to the Z+ limit switch connector on the CNC Shield. That Z+ pin on the shield should follow the tracks on the shield to Pin 11 on the Arduino. That will supply the PWM signal for the laser power modulation. The Black and Red wires of the laser should go to (I think) 12V @2 amps or more, more is ok but it will probably need at least 2 amps. Also you will have to set these 3 highlighted settings in GRBL settings in LaserGRBL. |

|

Thanks StuartB4. When we have the 3 pin module (VCC, GND, PWM), I have to connect VCC into external 12v 2+A power source (+) and GND into external 12v 2+A power source (-) and PWM into cnc sheild Z+. Is that correct? Do i need to connect the GND into (-) of the external power source and the GND of the arduino borad/cnc sheild? |

|

Yes that should work as long as the Z+ on the CNC shield is connected to pin 11 on the Arduino when the shield is plugged in to it. Yes you can make a connection from the - on the power supply to the GND on the Arduino, forgot to mention that. |

|

Thanks a lot |

|

I have some issues to clarify. Is there any code or method to control the power of 2500mw laser. Like when i need to engrave something lightly and when i need to engrave somthing hardly can i adjust the power of laser? |

|

Yes you can burn wood with a 500mw, and yes the more powerful the laser the more it will burn. The settings can be changed when you import your image in to LaserGRBL. The settings are then inserted in to the GCode when it's generated. So when you have your image imported and the settings how you think are ok you can save the GCode by clicking File, Save Program in LaserGRBL. Saving the program allows you to edit the code later if the burn was not as good as you thought. This example code is for a Vector engraving so the S power level is fixed @ 30, and the speed is set to 700 |

|

Thanks a lot..... |

|

These were all burned with LaserGRBL. The greyscale images were done with a 2 watt blue laser. The pencil is just so you get an idea of how small they are. |

|

Thanks a lot. If anything to add to learn, please be kind enough to update me. And you are explaining this well. Thanks again. |

|

yes it also enabled. |

|

i checked, it is also not commented. i measure the voltage by multi meter on D11(Z+) pin and GND, it shows the maximum voltage is 4.35v. |

|

the laser stays on does not turn off |

|

Can you help me please |

|

First, check proper working of your driver. |

|

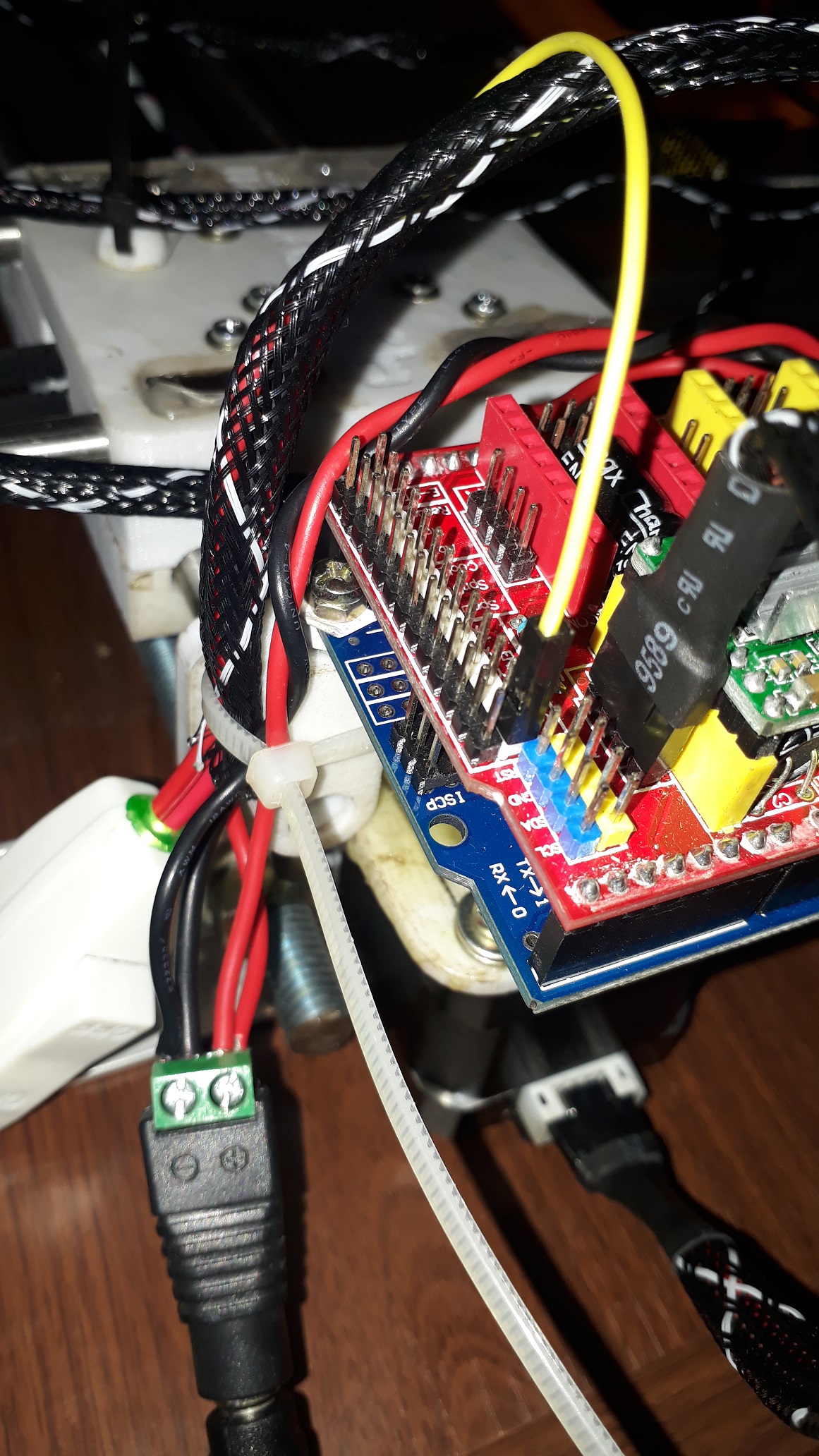

So: you confirm that pwm pin is not controlling laser on/off? If yes, your is an hardware problem. Could you post a picture of your boars and wiring? |

|

Change #define variable_spindle to #define variable_spindle true and recompile. |

|

Your 2 pin laser needs more power than that supplied by the Z+/- pin. You need a seperate laser driver board that has PWM connection. The laser driver board will either have it's own power supply to power the laser or it will get it from the main control board of the engraver. |

Thanks Stuart. I was starting to suspect that maybe not enough power was being output. I'll have to go through my "collection" and see if I have a driver board I can use. |

|

Oh yea, you can use either Z+ or Z- as they are both connected together on the shield circuit. |

|

Could i use a relay like below to provide more power ? |

|

The link you posted is not working. The link that shows up is this one https://github.com/arkypita/LaserGRBL/issues/url You could use a relay to switch the laser on but it will just be on or off, nothing in between, no variable power control. |

|

I fixed my previous msg links (I hope). So I think you are saying if I just want On/Off then a Relay will handle it but if I want to be able to control the laser strength I need a control board. If I use PWM with the relay that will just have the laser at full strength but with varying delay between the on/off ? |

|

If the relay you linked worked that way, the clicking sound would drive you mad, and the relay would die really quickly. Let's say the relay turns on at 3v. When your pwm reaches the 3v duty cycle, the relay closes, and your laser turns on at max power (if you have a 5v power supply), and remains at full power even is the duty cycle goes above 3v (like 4.4v or 5v). If it drops below 3v, the relay opens and your laser turns off completely, no in between values. |

|

If I use a laser driver like this does it convert the modulation input into varying voltages so that the laser strength is adjustable ? |

|

I've set up the steps per mm in Lightburn but when I go to "move" and set a distance of 30mm, the moving speed is either very very slow OR the axis moves towards the opposite direction. Is this something fixable? Did I flash the arduino the wrong way? |

I am not using Lightburn but I did have a problem using UGS when I first started. I had the FEEDRATE set to 1 so I would hear the motor but could see no movement. Once I increased it to 100 the motor actually would visibly move. Not sure if Lightburn has a similar setting but if it does try increasing it. As for the movement in wrong direction, did you set your HOME position properly or possibly invert your wires to your motor so they are running in reverse ? |

|

Before doing the axis calibration, the motors moved fast enough (more or less like my prusa i3 during rapids). Also the direction confusions don't happen every time. If an axis goes the wrong way and I hit stop and then hit the same move icon again, it goes where it's supposed to. This happens 3 times out of 5. |

|

@csanii123 Yep, that board should change your laser's power according to the PWM signal received from your arduino. @tornadomag Could you tell us more about your setup (engraver type, belt or bolt driven system etc and your |

It's an openbuilds acro 55 belt driven, using arduino uno r3 and cnc shield v3. Drivers are A4988. |

|

@tornadomag In that case, I suggest to take a look here. That FAQ might help a lot on compiling/flashing/setting up GRBL for your machine. If you have other questions about setting up your machine, please start a new discussion. |

|

You can flash it in LaserGRBL. On the Tools menu. |

|

@rahularepaka Since CNC Shield uses the Arduino pins in a way (it just comapcts them a little for ease-of-use), you can skip it if you want, using directly an Arduino. Arduino can generate PWM signals for you, which is then used by your laser driver board (the one on top of that laser module). Same as it would be with a CNC shield. |

|

@gmmanonymus111 But the laser only takes in 12 V at 5A but I am supplying 12V at 30A, won't it be a problem? and any idea what is voltage can the Laser module on the top take in cuz I couldn't find any documentation on it? Thanks |

|

That would work okay. If the PSU can produce greater current than the laser can take is not a bad thing, in fact, it is good (it could even operate your steppers on top of your laser module), so the 30A should be fine. Vattage in the other hand, should always be the same. So a 12V laser module should be always operated by a 12V PSU.

This means you can connect that PSU directly, as shown by your picture. |

|

@gmmanonymus111 Thanks for the quick reply! So I will do this wiring then! and the point of the laser is a different purpose it is to destroy weeds in my garden So, I will be writing a code with Analog Write Function and I will try it tomorrow and let you if it works? |

|

Sounds good to me, I'm interested in the results ^^ |

|

I have my laser "cutter/engraver" moving properly and laser turns ON/OFF. Parts: Arduino is powered by USB connection to computer GRBL settings:

|

|

@csanii123 I'm not sure a |

|

Other people on the Banggood website (where I bought the laser) say they have this cutting/engraving. I reduced the distance from 7cm to about 2cm but still no luck. I did mean 12V/30W as that is what the power supply is rated at. Perhaps that is the problem... I need a larger amperage power supply for the 12V laser driver. I'll try connecting the power supply directly to the laser driver and see if without the motors that works. |

|

Ok I swapped the 12V/30W power supply with a 600W PC power supply so should be more than enough power. Results: a) Other than getting a more powerful laser is there anything else I can do to make this better for cutting paper ? |

|

About the laser TTL pin and arduino, as I understand arduino pin PWM output is from 0 to 5V, but the laser specs states its PWM/TTL pin as being 0 to 12V If I understand things correctly, arduino feeding "full power" (5V) to the laser, it will be only at 41% of capacity because 5V is 41% of 12V (the maximum the laser accept). Arduino at 2.5V (half-power) will be just a bit more of 20% of the laser capacity (2.5V of 12V) Is this understanding correct? If so, do I need some kind of module to upscale the arduino output from 0-5V to 0-12V? If so, any recomendations on such a module? (I asked the laser manufacturer and they said the need for 12V is correct and state the board they sell outputs 0 to 12V, but I am using arduino, cnc shield and GRBL) |

|

If your laser is from 0-12V then you likely need a module in between. Also the Arduino can't output high current to power the laser so again you want a module in between to boost the current to the laser. |

|

I could not connect the laser module with 0-12 v pvm input to ender3 pro, which works with 24 v. Arduino produces 0-5 V PVM. The last user named csanii123 mentioned a module. Is this dc-dc converter module? |

I want to add 2.5w ttl/pwm laser module to my corexy plotter.

https://goo.gl/images/2awCuV

Please help...

The text was updated successfully, but these errors were encountered: