-

Notifications

You must be signed in to change notification settings - Fork 54

Cleaning & Servicing Guide

Previous Page Hardware Installation Guide

Next Page RF Capture Guide

VHS, Beta

Video8, Hi8, MiniDV

Note

Highlights information that users should take into account, even when skimming.

Important

Crucial information necessary for users to succeed.

Warning

Critical content demanding immediate user attention due to potential risks.

This breaks down into 3 categories

- Cleaning & Re-Lubrication

- Reflowing

- Repairing

Cleaning & Lubrication is the removal of old greases, dust, dirt, finger oils, shredded tape oxide your basic home user maintenance to ensure the mechanical hardware keeps working reliably.

Reflowing is the act of simply applying flux and new solder to electronics components and joints removing cold joints or cracked solder joints, such as on the head drum or amplification board.

Repairing is the act of replacing capacitors, replacing flex cables, integrated circlets (IC's) or very simple things like momentary switches for front panel buttons.

Firstly before you start even powering on or playing a tape in a new or unknown deck do the following.

-

Check the model number on the top or back label of the unit, use this to find the service manual online or inside the Discord or Wiki Pages.

-

Open the lid/top panel be careful around the edges on metal shells as the pressed cuts on the edges it can cut though skin if run across the edge carelessly, but should slide off upwards from the back of most standard VCR units after 4 screws.

-

Check for debris, dirt and outer contaminates on the decks tape path, this is when you should clean the deck and run a low value test tape though it to verify working state.

- Set of Brushes (Dusting off components)

- Lint Free Microfiber Cloth ("Ultra-Fine") ("Nail Wipes" are the Ideal size ones to get) (PEC pads are the same stuff)

- Isopropanol 99.9% (IPA/Rubbing alcohol) (Never use 40/60/70% due to water content)

- Acetone 99.9% (NEVER USE ON PLASTICS, for extreme case head/metals cleaning)

- Q-tips (Cotton Buds/Sticks/Swabs)

- Wet Wipes (Demonised Water or Lysol)

- Paper Towels (Cleaning in general if lots of dust)

- Air Blower (blow away fibres and large dust chunks)

You can also get:

- Chamois Towels (Sheets of Chamois)

- Chamois Swabs (Very expensive only worth it for getting into camcorders, or make your own at home with sheets)

Lubricating

-

Super-Lube® Multi-Purpose Synthetic Grease (PTFE) (Tape Guides, Plastics, Cogs, Pinch Roller) Loctite 399420

-

Generic Sowing Machine Oil (useful on metal bearings such as pinch roller and all metal gears)

Warning

Acetone can be used to remove very tricky dirt on heads and drums, but can never be used on plastics or PCBs haphazardly as it will melt the plastics & soldermask away, its also helpful if you ever want to destroy adhesives like cheep tissue tape used on heat syncs that should have thermal pads instead.

- Soldering Iron - Bevel/Flow & Chisel Tips

- Desoldering vaccume gun

- Multimeater / Ossiliscope -

Cleaning a VHS Head Drum

Cleaning a Camcorder (Video8/Hi8/Digital8/MiniDV)

This varies based off year and market of the VCR modern later decks use more multirole IC's, ware as prosumer to rackmount units will have core parts for each processing task on dedicated boards and be majority though hole parts

Panasonic NV-HD630 For Example

Important

Numbered Boxes In RED test point locations for signals, these are different from deck to deck.

Left Hand Side

- Pink - TV Modulation & De-modulation pack

- Golden Yellow - Audio Processing (NICAM)

- Bright Yellow - Video Processing

Middle

- Purple - Head Amplifier Board (direct Video/HiFi RF)

- Blue Box - VCR Loading & Playback Mechanical System or "Mech"

- Yellow Circle - VCR Head Drum & Connection Board

- Green Circle - Tape Guides & Guide Path

- Light Blue Left - Erase Head

- Orange Circle - Linear Audio or Edge Track Audio Heads

- Light Blue Right - Rubber Pinch Roller

- Brown Boxs Center/Right - Head Drum RF Ribbon

Right-hand Side

- Red - AC Power Supply Stage

- Green - DC Power Supply Stage

Warning

Be careful to not haphazardly touch the mains power supply area this can shock you and or kill you if you bridge the AC stage.

Generally, these have metal shielding and are isolated off to one side of the VCR, always service equipment after it has been un-plugged and discharged of power unless you know what you are doing.

Always Inspect & clean a VCR before running a tape though, it is the best first action, not only so you don't contaminant or break your tapes but to verify the deck is in good working order and already been serviced just clean the heads, and give the drum a light once over.

Check that tape guide tracks are well lubricated if it looks shiny then there's not enough. Pinch rollers bearings can be lubricated with a drop of oil, and guides can be cleaned with wipes then use 99.9% Isopropanol.

Once cleaning has finished double check, if there are any signal issues, best to also check if there is cracked solder joints on the head drum from transport.

Note

Always remove the head cleaner off the side of the drum if there is one, as they are just dirt spreaders and can cause contamination and cant beat a proper manual deep, and light cleaning.

Its a complex concept involving (C6H1O5)n & C3H8O

That's a joke, its paper and 99.9% rubbing alcohol.

Simply cut a paper strip printer paper works fine, fold once, wet with alcohol, press on the drum not onto heads directly lightly and hand rotate slowly do not go up and down and always gently pull away from drum once you have rotated for 10 seconds repeat until paper is clean.

It’s recommended to first clean around the drum. Clean around the entire drum cylinder, including its track (this is the metal rim that aligns the tape). Clean the tape guides / rollers with swabs; however, never use a cotton swab or Q-Tip on the video heads, as the fibers can damage them.

Cotton swabs are safe to use on linear audio heads, which are the flat metal contacts. That’s really it: clean heads and lubricated mechanical tracks are all a VCR needs to ensure the best results.

Tip

Be sure to clean both before and after use to prevent any contaminants from cross-contaminating tapes.

Tip

Betamax players using only alcohol-wetted paper is recommended for head cleaning as they will catch easily on anything else, heads on decks such as VHS are able to use slightly more abrasive such as microfiber towels, Nail wipes or PEC pads.

Guides

The rollers that take tape and wrap it around the drum, should be wiped off with upwards and downwards motion with a cloth or in an angle with cotton buds.

Guide Tracks

Use dry and or wet wipes to remove old grease then apply some Isopropanol to the wipes and do a Isopropanol only wipe to finish.

After it is clean and dry apply a coat of super-lube grease on both sides with a gloved finger or cotton bud, run a test or throwaway tape though the vcr to move the lubrication a though the guides, remove excess after repeating this 2-4 times.

Pinch Roller

Use a microfiber cloth with just clean water for basic cleaning, do not use alcohol or chemicals that can dry the rubber.

Depending on the type of baring you may use sowing machine oil or just super-lube grease internally, normally 1-2 drops of lubrication on its baring can be a quick fix to squeaky rollers, if vertical mounted you may need to apply a light coat of thread lock to the post that connects to the baring

If the roller was exposed to mould, it's best to fully remove, wash & dry with lint free cloths and re-lubricating the baring before re-installing.

Tip

If the baring is removed from a vertical mounted post and does not go back on securely, apply a light coat of threadlock to the bearing post and support it lightly, after re-attaching the roller bearing.

Head Drum

Cut a small strip of printer paper, fold once wet with Isopropanol wait a second then apply to side of drum with one hand then with the other from the top not side of drum hand rotate it for 10-seconds before changing paper, repeat until paper is clean, alternativly you can also use Chamois swabs.

Warning

You can use cotton swabs to clean the drum rim and top, but never run/rub acrss the heads!

Erase Head & Linear Audio / Control head

Clean with cotton swabs, wipe with microfiber cloth ensure no debris.

Power, Motor Driver

Clean with 99.9% IPA and cotton swabs, wipe with microfiber cloth ensure no debris, connectors and connections can be diffrent. (example is the Panasonic K-Mech).

This is done to ensure electrical contact is clear and clean.

Good solder joints are paramount to good electrical signal transmission weather it be power or audio/video/data signals, a broken/cracked/cold joint means issues.

Reflowing, apply flux, apply heat with a clean bevel or chisel tip.

De-soldering & fresh solder, apply flux, apply copper braid and then iron at 280-340c to all joints for connectors leave the last 2 end pins and do them after re-soldering 1-2 middle pins.

Tip

De-soldering vacuum guns are great tools for saving time removing solder and saving your PCBs pads from mechanical and thermal stress and aids in recovering of thru-hole components.

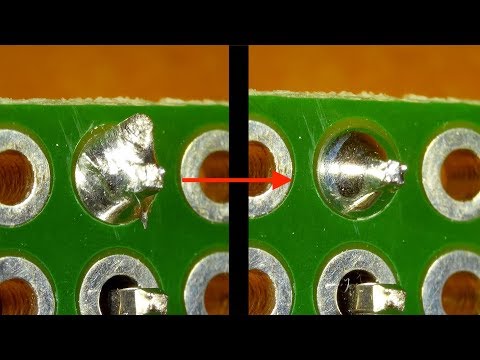

Cracked Joints Example on a head amplifier module to the head drum of a VHS VCR.

Note

Having a 3rd arm holder with at least 2 metal clips is very helpful to hold connectors/cable and small PCBs steady while soldering or inspecting them.

Video:

Note

The PINCEL/TS101 is recommended as it can run off USB-C PD or DC power and tips can be hot swapped on the fly, however ensure use of a grounded to earth USB-C power supply or run a external one if direct DC when working with sensitive parts.

Note

A clean & tinned soldering tip is a happy long-lasting tip a light coat of solder or tinning is for good heat transference and for protecting the iron from oxidisation after use, alongside using brass wire ball and never sponge cleaners.

This chapter contains overview information of understanding what things can be calibrated, as the exact steps slightly differ per VCR and format depending on the service manual.

| Maladjusted | Adjusted |

|---|---|

|

|

Previous Page Hardware Installation Guide

Next Page RF Capture Guide

- FAQ - Frequently Asked Questions

- Diagram Breakdowns

- Visual-Comparisons

- VCR Reports / RF Tap Examples

- Download & Contribute Data

- Speed Testing

- Visual VBI Data Guide

- Closed Captioning

- Teletext

- WSS Wide - Screen Signalling

- VITC Timecode

- VITS Signals

- XDS Data (PBS)

- Video ID IEC 61880

- Vapoursynth TBC Median Stacking Guide

- Ruxpin-Decode & TV Teddy Tapes

- Tony's GNU Radio For Dummies Guide

- Tony's GNU Radio Scripts

- DomesDay Duplicator Utilities

- ld-decode Utilities