Releases: CrealityOfficial/CrealityPrint

v5.1.1

Feature:

- Added multiple process parameters:

- Quality: Scarf joint seam, Arc tolerance, Don't filter out small internal bridges(beta), Minimum wall length, Wall loop direction, Small area flow compensation (beta), and Flow compensation model, Bridge counterbore holes.

- Strength: AI infill, Apply gap fill.

- Added Model integrity detection and Repair functions (Windows).

- Added Part, Negative part, Modifier, Support enforcer and Support blocker functions.

- Added 3MF project file upload to Creality Cloud.

- Added Spherical brush tool (seam painting, color, support painting).

- Added support for Japanese, Korean, and French languages.

- Added multiple calibration functions: Retraction speed, Speeds (maximum speed, speed tower, jitter speed, fan speed), Accelerations (max acceleration, acceleration tower, slow acceleration), Arc fitting.

- Add acceleration information during the acceleration process in slicing preview.

- Upgraded user feedback system.

- Added more error message prompts.

- Increased speed of re-slicing after parameter modification.

- Optimized some interaction operations.

Fixed:

Fixed other known bugs.

v5.1.2

Feature

- Add Epoxy resin platform board.

- Optimize the login of Creality Cloud.

- The wiping tower has added a diagonal stability and anti collapse function, which can be switched and used with the existing stable cone.

- Optimize parameter input jump interaction. After entering the value, press the tab to jump to the next parameter input box.

- When repairing multiple slices, always start cutting from the first disc. The issue of not cutting from the current disk.

Fixed

- Fix the issue of overlapping between the current disk model and the first disk model in multi disk slice preview.

- Fix the issue of different material parameters and settings in exported GCode slices.

- Fix the calibration of slicing software - the pressure pre calibration function was not sent as a calibration gcode file.

v5.1.2

Feature:

- Added support for multiple languages: Russian, Spanish, Portuguese, Turkish, Ukrainian, and Polish.

- Introduced a new text embossing feature.

- Fixed an issue where models could not be flattened due to errors in the surface flattening algorithm.

- Resolved an issue preventing the use of the object exclusion feature during LAN printing.

- Corrected a problem where custom machine types triggered a printer selection mismatch error when sent over LAN.

- Fixed a bug preventing modification of VFA calibration values due to the cutting function.

- Addressed an issue where mouse pointer offset in certain graphics card environments caused functionality buttons to be unclickable.

- Optimized rendering efficiency to reduce lag issues when working with large memory models.

- Collaborated with Creality Cloud to optimize and filter out inappropriate content.

Fixed

- Fixed an issue where the shell extraction function did not operate correctly.

- Fixed an issue where imported Gcode files would have their file size reduced to 0KB.

v5.0.3

Windows:

Feature:

- Add the "Print infill first" parameter in advanced technology

Fixed:

- Fix the issue of user feedback that installation protocols not displaying in different languages

- Fix the issue of user feedback that there is deviation when clicking on the software with the mouse

- Fix the issue of user feedback that incorrect system version display on the Error Report page

- Fix the issue of no isolation between domestic and overseas parameter environments

- Fix the issue of adjust the effective position of the cavity temperature command in Gcode

- Fix the issue of incorrect preview image display when importing local Gcode and sending LAN printing

- Fix the issue of CXPRJ file not reading consumable colors

- Fix some crash issues

- Fix some UI display and compatibility issues

- Fix other known issues

Mac:

Fixed:

- Fix the issue of abnormal data position display after model ranging

- Fix the issue of abnormal display of temperature calibration model when the color display type on the preview page is temperature

- Fix the issue of not displaying personal center and download management entrance

- Fix the issue of abnormal loading of model parameters causing the inability to create a new model

- Fix other known issues

Creality Print 5.0.2 Release Notes

Creality Print 5.0.2 Release Notes

Bug Fixing

- Fix known issues

Creality Print 5.0.0 Release Notes

Creality Print 5.0.0 Release Notes

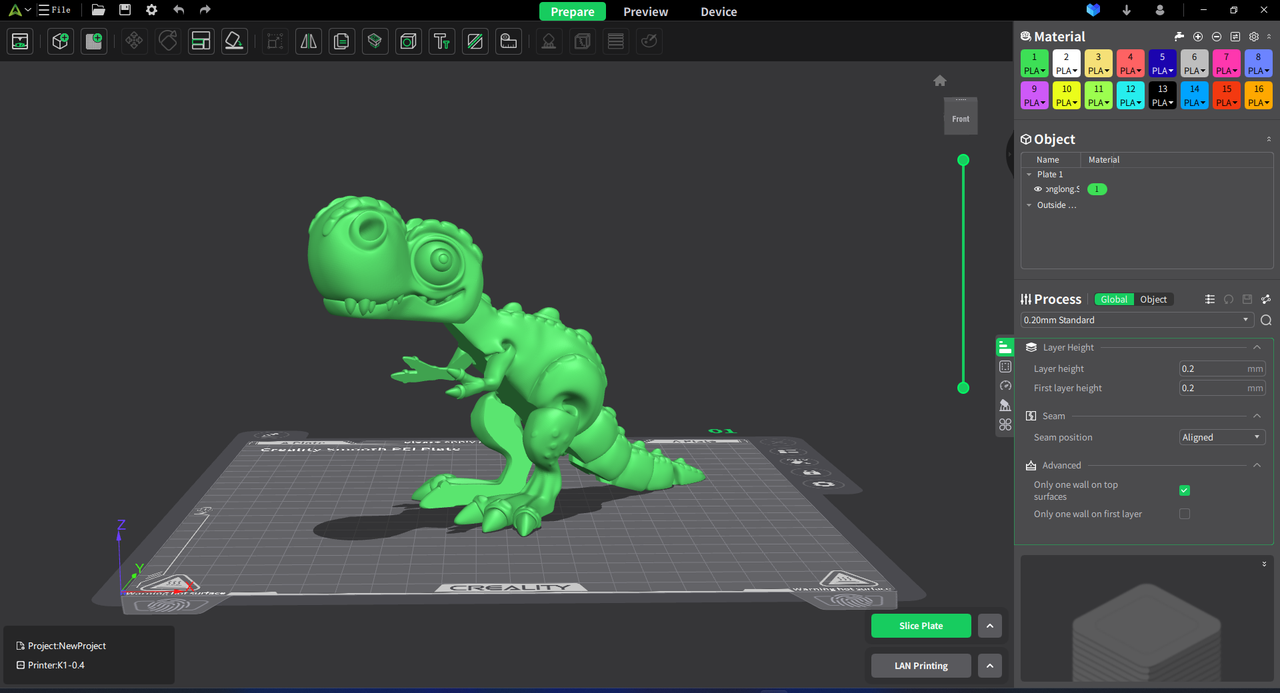

We are delighted to announce that the brand new version 5.0 has been released officially, with all upgrades aimed at improving user experience.

Firstly, with a new user interface and interaction experience, the process settings system has become simpler, and the slicer has become more user-friendly and intelligent. The K series/v3 high-speed machines now support 42 kinds of official filaments and general parameters. We have not only readjusted the machine process parameters, but all parameters can be saved and exported for sharing.

Moreover, through our ongoing efforts, version 5.0 has faster printing speed and better printing quality.Now let's see together what other surprises there.

1. Key Improvements

1.1 Revolutionary User Experience

Comprehensive Upgrade of UI

- With the upgrading of the company's Corporate Identity (VI) system to version 5.0, we have rolled out a fully revamped UI system. A brand-new logo, theme color, icons, and page layout will be introduced to provide users with a fresh visual experience.

- We adjusted the UI layout after the upgrade according to mainstream visual habits: we repositioned the toolbar and prioritized the process setting systems. This made the operation interface clearer, not only reducing the operation steps for settings, but also greatly enhancing the smoothness of the user experience.

Printing Becomes a Piece of Cake

- After extensive model testing and parameter adjustment, we have developed several configurations for different machines and nozzle types. You can conveniently select an appropriate configuration for one-click printing. For instance, we offer four configurations for the K1C-0.4 nozzle.

- We constantly monitor the processing status of the model to minimize any factors that could negatively affect print quality. Should there be any issues, our user interface will promptly provide friendly cues in the bottom-left corner, assisting users in promptly identifying and resolving the issue to minimize any potential losses.

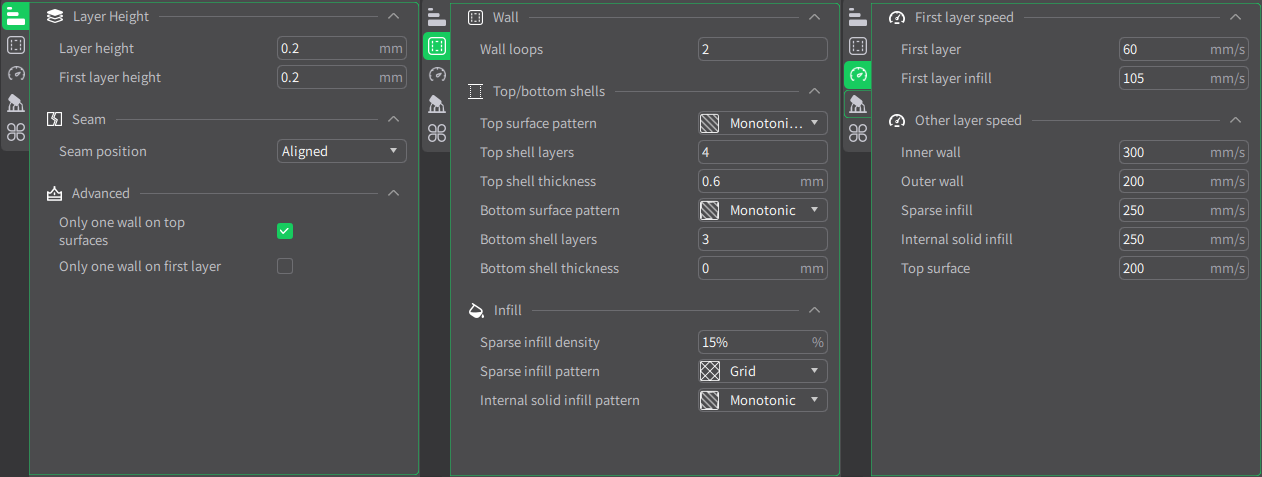

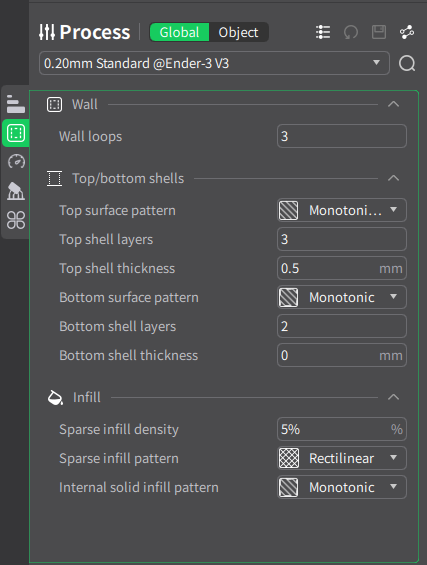

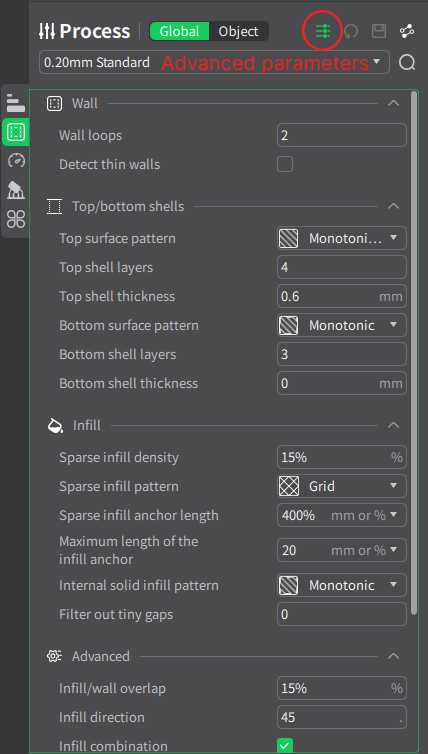

- The variety of settings often causes confusion. For this reason, we have selected a set of commonly used parameters as the basic settings, enabling you to quickly adjust common parameters and diminish the impact of unnecessary information.

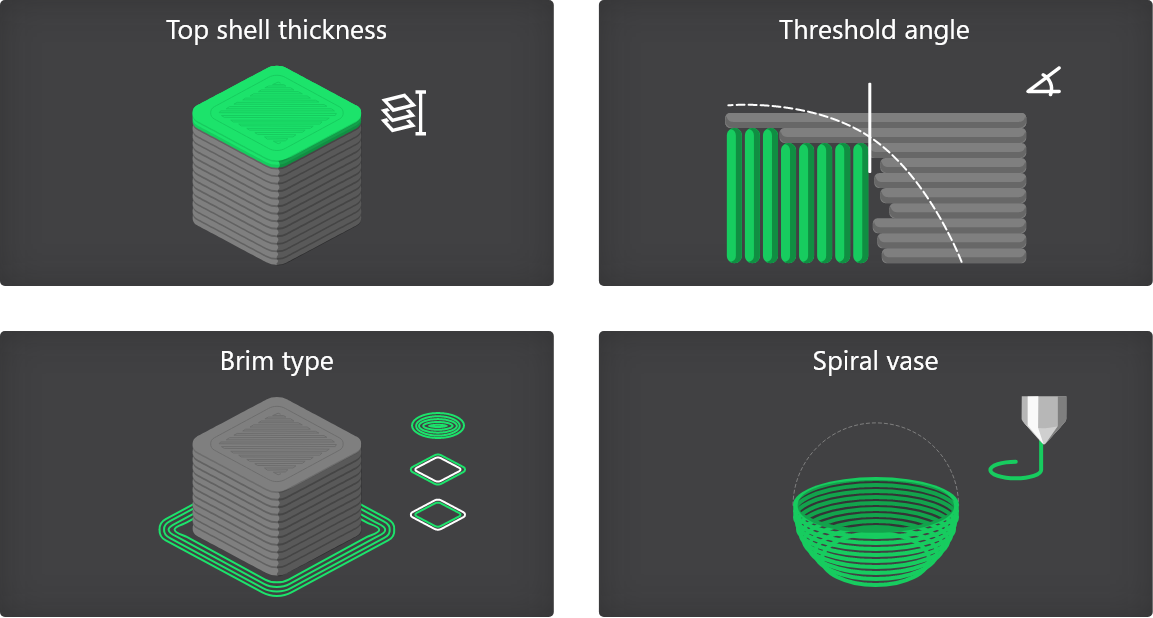

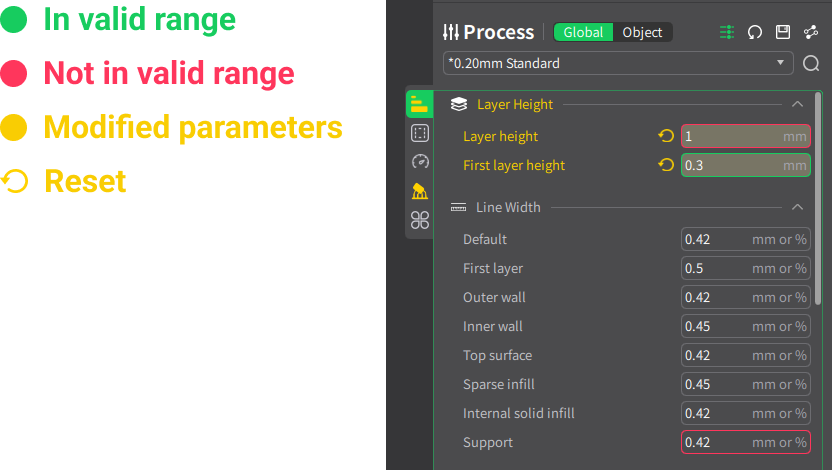

- 5.0 Version introduces a wealth of diagrams for parameters, illustrating complex parameters in an intuitive way. Along with these diagrams and elaborate descriptions, you can quickly understand the meaning of each parameter.

More Efficient Process Tuning

- Indeed, we also accommodate more extensive parameter configurations. Simply switch to the advanced settings mode to access comprehensive parameter information, facilitating broad and meticulous adjustment.

Normal

Advance

- Evidently, the valid range of parameters is closely associated with various factors such as the types of consumables and the device model. This often makes it challenging for users to accurately judge the validity of settings. To address this issue, we have established a suitable range for each parameter and provided a color-coded input box. This allows users to easily determine the status of parameters while making changes.

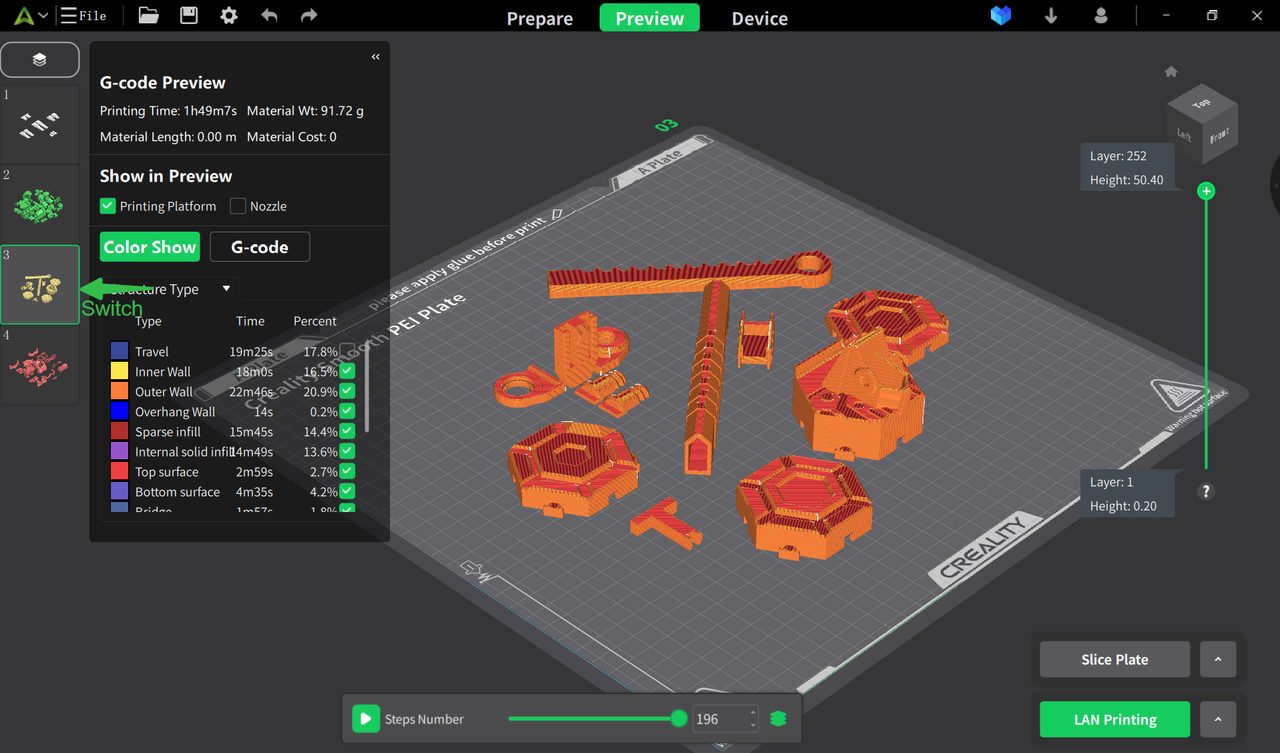

- Previewing slices has now become WYSIWYG - what you see is what you get. We now support real-time parameter modifications during previews, enabling you to rapidly observe the effects of your adjustments.

More Convenient Professional Settings

- We not only support global settings but also offer flexible and detailed solutions. When printing multiple models in the same job, you can use object settings to apply individual parameters to each model. Each model is sliced with the parameters that suit it best, effectively enhancing the print quality and efficiency.

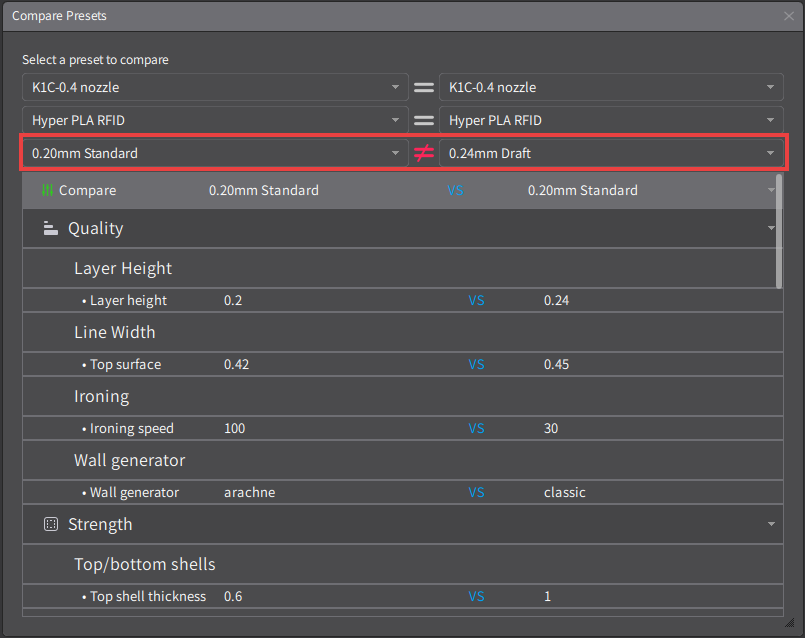

- Supports the comparison of different types of machines, materials, and process parameters. By using this feature, you can thoroughly compare the differences,to find out the key parameters affecting quality, providing guidance on the optimal direction for your printing tasks.

1.2 Settings Configuration Upgrade

- Upgrade Of Default Parameter Configuration

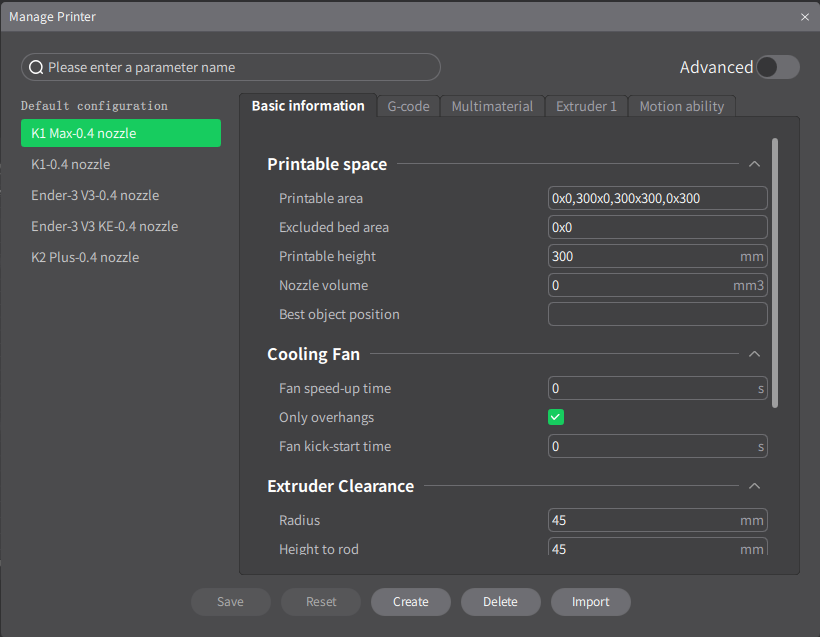

Creality Print provides an array of tested and official print configurations, encompassing aspects like printers, filaments, and process settings. These configurations, verified through extensive testing, are designed to guarantee successful printing in the majority of cases, and simultaneously meet essential printing needs.

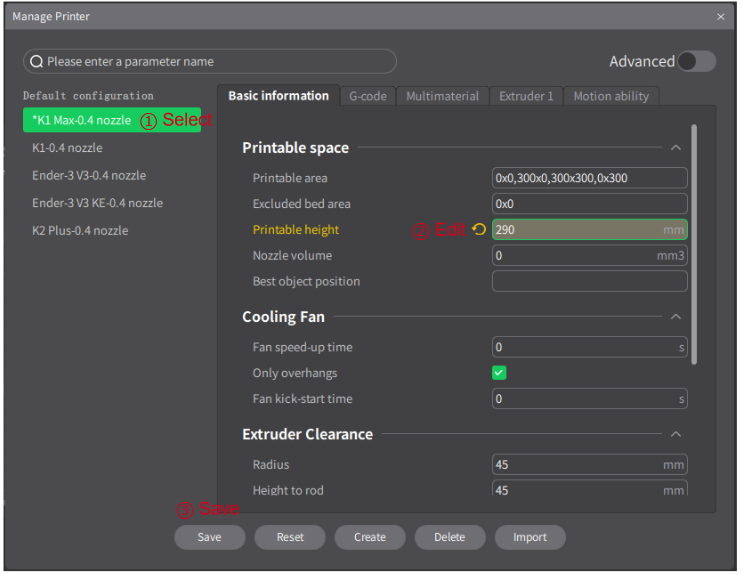

(Printer)

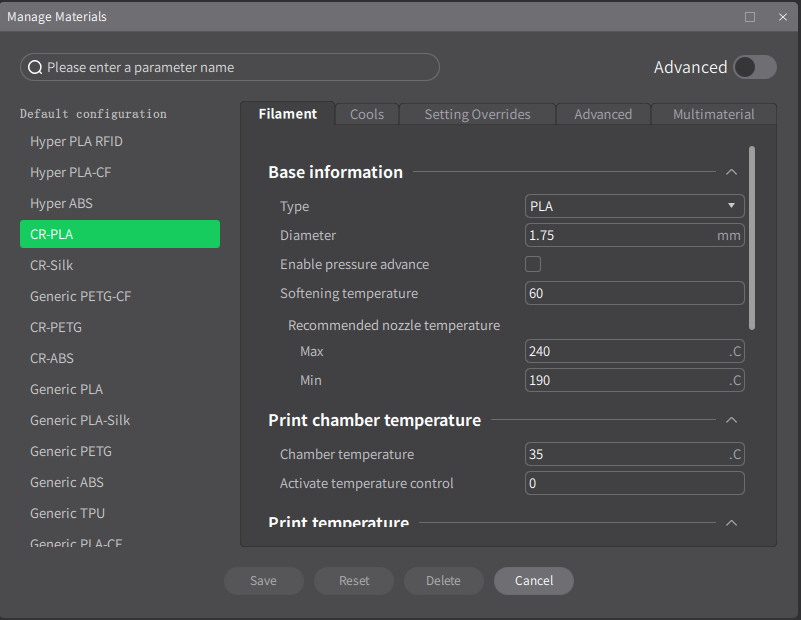

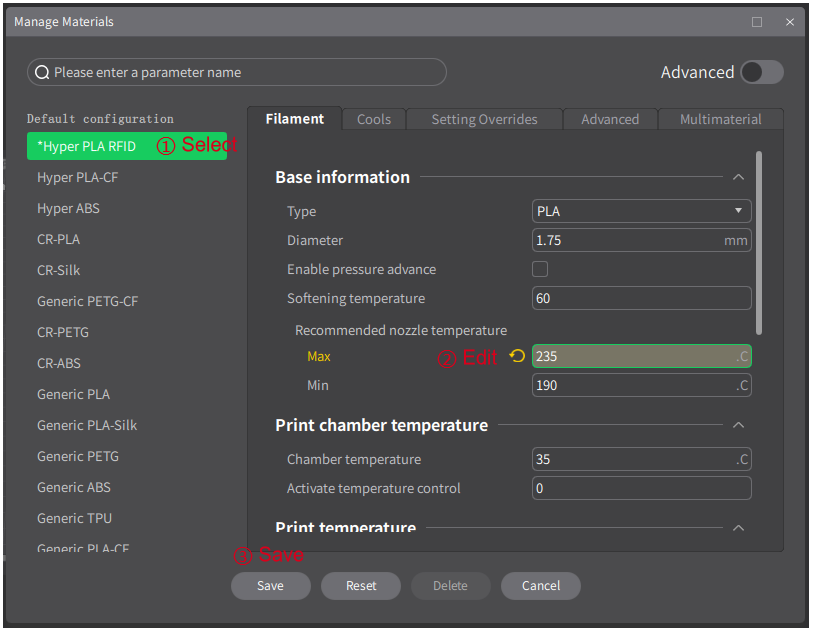

(Filament)

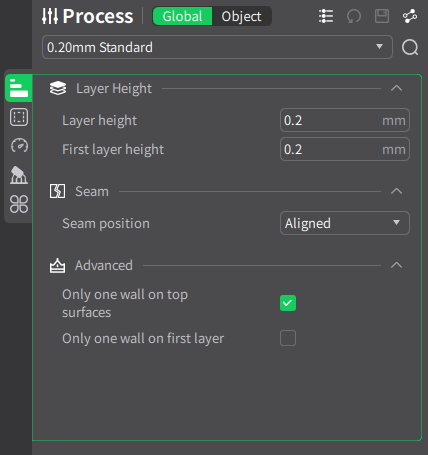

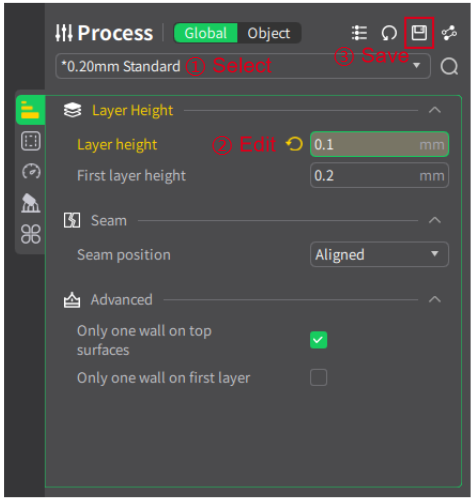

(Process)

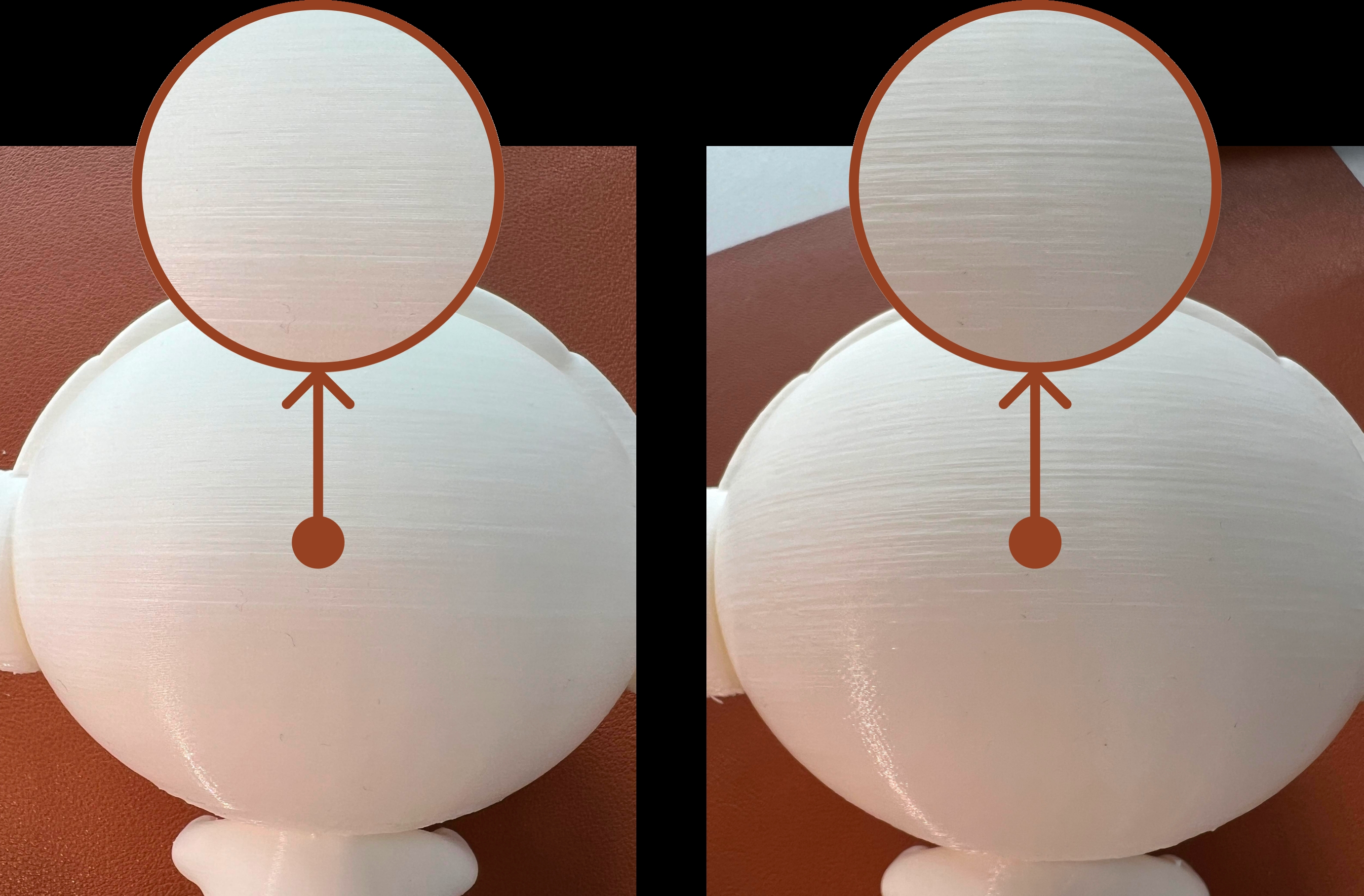

A noteworthy update in the brand new 5.0 version is that we've upgraded and made great efforts to the printing configurations, with the aim of enhancing your printing experience. For instance, when printing the model in the following model on the same printer,using the default process settings of 0.2mm Standard process parameters, the print quality in version 5.0 is noticeably superior to that in version 4.3.8.

(5.0) (4.3.8)

(5.0) (4.3.8)

- Upgrade Of User Preset Configuration

Simplify your printing process by creating custom slicing parameter presets for regular use according to your distinct print demands and habits, such as settings for other filaments. You can base these on official configurations, and save them to Creality Print, or export them as a Zip for reuse or sharing with friends.

(Printer)

(Filament)

(Process)

The noteworthy aspect is the 5.0 version's compatibility with other slicer software exported user presets, such as Prusa and Orca. This allows for a variety of configurations from different software.

Furthermore, you can share and exchange your parameter configurations using 3mf project files. As a universal third-party standard file, 3mf offers richer and more accurate data descriptions compared to other formats. When using 3mf project files, not only printers, filaments, process settings, but also your databank for support coatings, Z-Seam drawing data, adaptive layer heights, etc., can be seamlessly used across multiple software platforms.

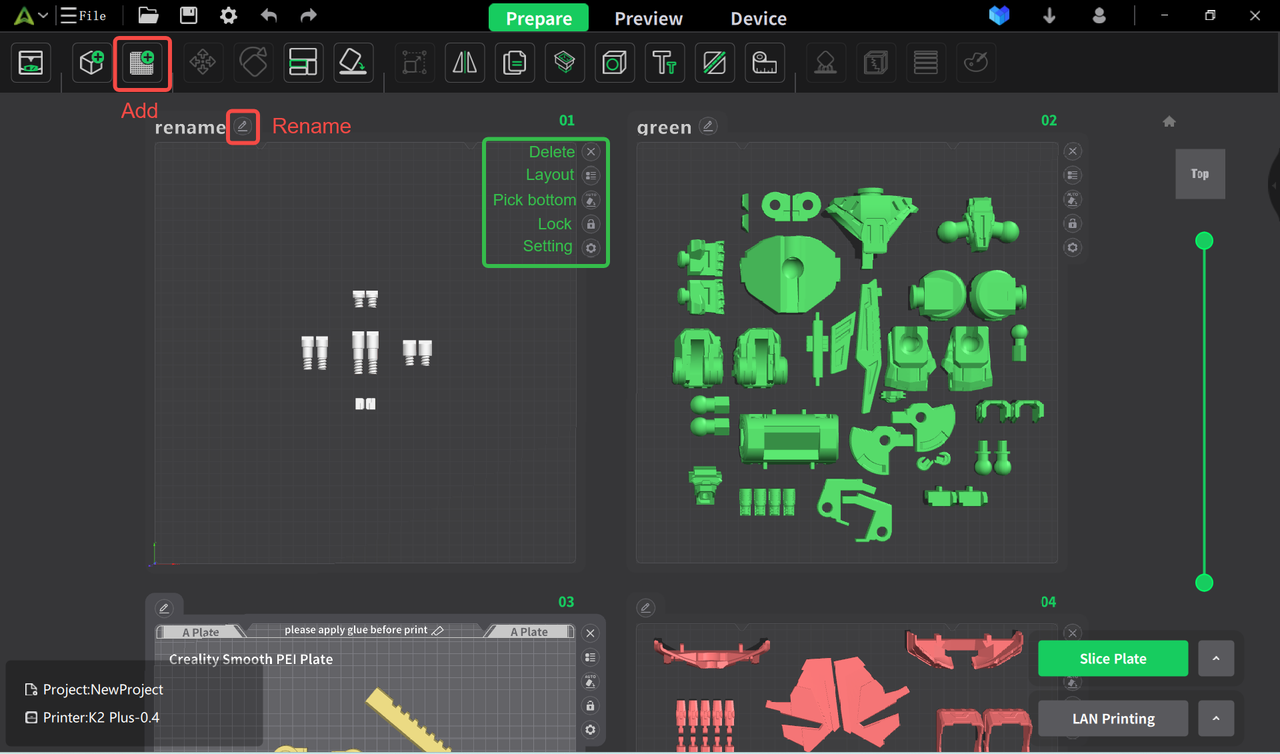

1.3 Efficient Multi-Plates Management

In the past, when printing splicing structural models, we had to manually group a large number of models on a print plate and store them in multiple files for printing. This process was somewhat cumbersome, prone to error, and very time-consuming. Now, with multi-plates management, you can consolidate all the parts need to be printed in one file to increase convenience and operation efficiency in classifying models, making it easy to handle the printing tasks of multiple models.

primary functions:

- Supports regular operations of the plate, such as adding/removing/selecting/customizing names/locking, etc.;

- Supports automatic layout and orientation of the current tray model, and you can also manually drag to adjust;

- Supports saving the plates to 3MF and CXPRJ files for easy subsequent editing;

- Supports quick switching between different trays to perform slicing, previewing, and printing.

2. Performance and Quality

2.1 Faster Printing Speed

The printing speed of the model is influenced by not only the hardware but also the slicing algorithm optimization. Thanks to algorithm improvements in version 5.0, a very apparent enhancement of printing speed, ranging potentially between 20% and 50%, though the exact percentage would vary based on model structure and printing process.

There are two key factors contributing to these speed improvements.

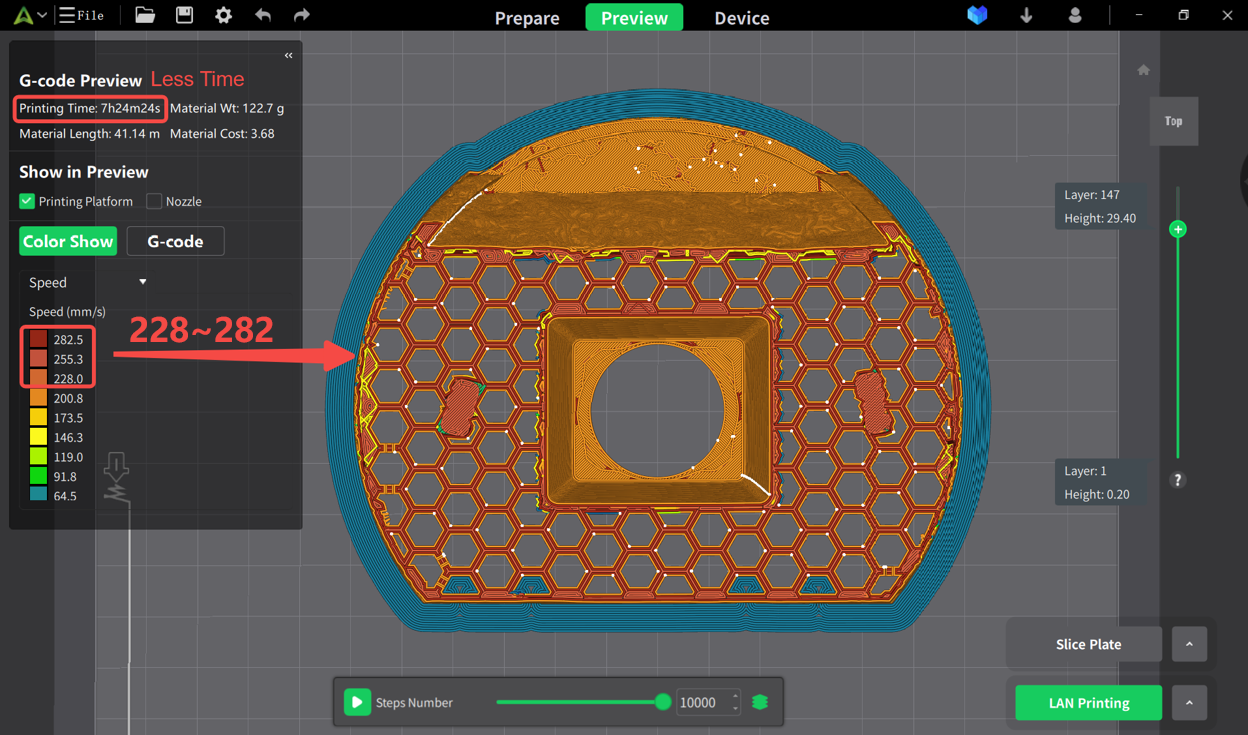

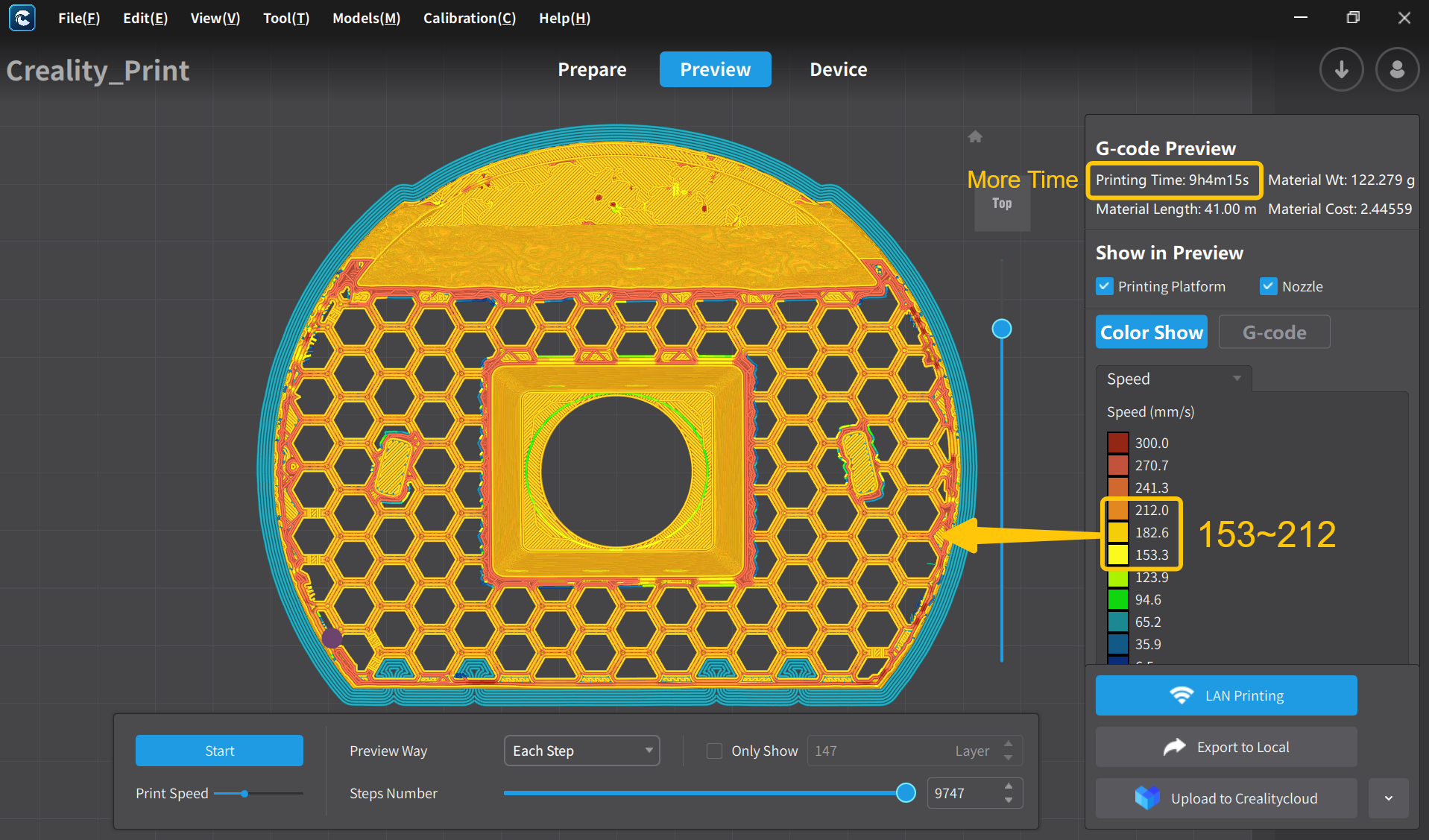

First, efforts have been made to greatly increase the speed of certain types of lines, specifically the inner and outer walls, while still ensuring printing quality. As the graphic shows below, version 5.0 presents a visibly higher speed (indicated by color) for the lines of the inner and outer walls on each level compared with the previous versions.

(Printing Time of 5.0:7h 24m 24s)

(Printing Time of 4.3.8:9h 4m 15s)

Next, we have improved the continuity of 3D-printing paths and attempted to follow the shortest routes in the printings. Below you will see the printing pathways of both the old and new versions in the same layer. You may intuitively find that the path planning in the...

V4.3.9

New Printer:

- Nebula Screen adds Ender-3 V3 SE printer adaptation

- Sonic Screen adds 8 compatible printers: Ender-5 plus, CR-10 V3, Ender-3 Max Neo, CR-10 S4, CR-105, CR-6 Max, CR-M4, Ender-3 V3 SE

New Features:

- Tools-Language, more language versions (18 in total)

- Z-Seam paint function

- Support paint function

- Add commonly used test model functions to the file menu

Optimization features:

- Printing platform shape and button functions

- Support optimization (automatic normal support, automatic tree support, manual normal support, manual tree support)

- The mouse operation of the platform and model is optimized, and the cursor display for rotation, movement, and frame selection is added

V4.3.8

New printers:

- Added Nebula screen category and 4 compatible printers (Ender-3 V2, Ender-3 V2 Neo, Ender-3 Pro, Ender-3).

- Added 6 new sonic screen compatible printers (Ender-2 Pro, Ender-3 Pro, CR-10, CR-10S V2, CR-200B, Sermoon D1).

- Added Ender-3 V3, K1C, CR-1000S, GS-01 printers.

new features:

- Added Korean adaptation.

- Added slicing progress bar information display.

- Add object exclusion function.

- Add a sorting function to the file list on the LAN device details page.

- Progress display when exporting LAN files.

- Matching of G-code and machine model when printing on LAN.

- The wall printing sequence adds a flexible wall printing sequence. (for drape, use the inner wall first and then the outer wall, and for others, use the outer wall first and then the inner wall);

Optimization features:

- Improve the LAN printing function.

- Accurately match the model fan/side fan/back fan/LED light function information with the printer.

- Optimized the wiping printing path algorithm.

- Optimize suspension deceleration algorithm.

- Optimize model layout function algorithm.

- Optimize the maximum number of model clones.

- Optimize the model lettering function algorithm.

- Optimize system memory usage.

- Improve model rendering performance.

Key bug fixes:

- Fixed the problem that the positioning device cannot be found after the IP of the LAN device is changed;

- Fixed the problem of slice preview playback;

- Fixed calibration-temperature tower preview abnormality problem;

- Fixed the issue where the G-code preview information during slice preview is 0;

- Fixed the issue where the slice continues to prompt for support when supports have been added;

- Fixed the problem of missing steps when printing model slices when dither speed control is enabled;

- Fixed the problem of abnormal display of slice preview support;

- Fixed the problem of automatic layout after model cutting and the model is not on the same horizontal plane;

- Fixed the problem of model scaling - the operating software crashes after unlocking the proportion;

- Fixed the bug that the gcode file name generated by cloning multiple models is too long;

- Fixed the issue where certain models crashed;

- Fixed the problem of project file crash;

- Fixed the problem that laser and CNC models cannot be used;

- Fixed some link issues in Creality Cloud;

- Fix other known issues;

v4.3.7

New features:

- Added functions for renaming, deleting G-code of LAN devices.

- Added functions for renaming, deleting and sharing time-lapse photography files of LAN devices.

- Added CR-10 SE and Ender-3 V3 KE printers.

- Added 10 new sonic screen compatible printers.

- Added Aligned Rectilinear filling method.

- Added support judgment function when slicing.

- Added G-code sharing function in crealitycloud Personal Center.

- Added new prompts for models that are too large or too small when importing.

Optimization features:

- Optimize the language and server selection when starting the software for the first time.

- Optimize the update the slicing configuration of Ender-3 V3 SE, Ender-3 S1, Ender-3 S1 Pro, Ender-3 S1 Plus, Ender5 S1, K1, K1 Max, and Sermoon D3 Pro.

- Optimize the temperature and flow preview of calibration function.

- Optimize the large model import and slicing performance.

- Optimize the the speed and success rate of tree support generation.

- Optimize the the printing effect of the active model.

- Optimize the top printing effect.

- Optimize the accuracy of G-code printing information.

- Optimize the temporary documents and project documents.

- Optimize the interaction on the left operation bar.

- Optimize the model download center sorting.

- Optimize the LAN device status, network update, printing control.

Key bug fixes:

- Fixed known slice stuck and crash issues.

- Fix the problem of G-code file upload in LAN.

- Fixed G-code file generation, saving and parsing issues.

- Fixed CR-30 adhesion and slice display issues.

- Fixed Sermoon D3 Pro printing logic and heating logic issues.

- Fixed the clone function of Linux version .

- Fixed the Mac version non-default Z-seam slicing crash, parameter configuration display, project file and model upload issues.

- Fixed the problem of flattening the model.

- Fixed notebook windows 11 system and 4K resolution compatibility issues.

- Fixed parameter linkage, operation, ineffectiveness and translation issues of the parameter system.

- Fixed display and slicing logic issues when the model exceeds bounds.

- Fixed the problem of importing image files to generate models.

- Fixed model rendering, preview and display issues.

- Fixed the problem of remote printer retracting parameters.