This is the newest version of the Marlin Firmware, customized and optimized for the Anycubic i3 Mega, based on my Marlin-Ai3M repository.

While I will try to keep this version updated with the latest changes from the Marlin firmware, for now the old readme and Wiki still applies.

Looking for a BLtouch firmware? Head this way! Mounting and configuration instructions are included.

A German translation of the instructions can be found here.

While the i3 Mega is a great printer for its price and produces fantastic results in stock, there are some improvements and additional features that this firmware provides:

- Many people have issues getting the Ultrabase leveled perfectly, using Manual Mesh Bed Leveling the printer generates a mesh of the flatness of the bed and compensates for it on the Z-axis for perfect prints without having to level with the screws.

- Much more efficient bed heating by using PID control. This uses less power and holds the temperature at a steady level. Highly recommended for printing ABS.

- Fairly loud fans, while almost every one of them is easily replaced, the stock FW only gives out 9V instead of 12V on the parts cooling fan so some fans like Noctua don't run like they should. This is fixed in this firmware.

- Even better print quality by adding Linear Advance, S-Curve Acceleration and some tweaks on jerk and acceleration.

- Thermal runaway protection: Reducing fire risk by detecting a faulty or misaligned thermistor.

- Very loud stock stepper motor drivers, easily replaced by Watterott or FYSETC TMC2208. To do that, you'd usually have to flip the connectors on the board, this is not necessary using this firmware.

- No need to slice and upload custom bed leveling tests, test it with a single GCode command

- Easily start an auto PID tune or mesh bed leveling via the special menu (insert SD card, select special menu and press the round arrow)

- Filament change feature enabled: Switch colors/material mid print (instructions below) and control it via display.

- The filament runout, pause and stop functionality have been overhauled and improved: The hotend now parks and retracts (on pause or stop) and purges automatically (on resume).

- Added

M888cooldown routine for the Anycubic Ultrabase (EXPERIMENTAL): This is meant to be placed at the end Gcode of your slicer. It hovers over the print bed and does circular movements while running the fan. Works best with custom fan ducts.- Optional parameters:

T<temperature>: Target bed temperature (min 15°C), 30°C if not specified (do not set this under room temperature)S<fan speed>: Fan speed between 0 and 255, full speed if not specified- e.g.

M888 S191 T25: run the fan at 75% until the bed has cooled down to 25°C

- Power outage support is not included

- Estimated print times from your slicer might be slightly off.

- Special characters on any file or folders name on the SD card will cause the file menu to freeze. Simply replace or remove every special character (Chinese, Arabic, Russian, accents, German & Scandinavian umlauts, ...) from the name. Symbols like dashes or underscores are no problem. Important note: On the SD card that comes with the printer there is a folder with Chinese characters in it by default. Please rename or remove it.

I provided three different precompiled hex files: One for no modifications on the stepper motor drivers - good for people who didn't touch anything yet, one for boards with TMC2208 installed and where the connectors have been flipped and one with TMC2208 and the connectors in original orientation.

- Download the precompiled firmware here: Releases

- Choose the correct hex file:

- For TMC2208 with connectors in original orientation, use

Marlin-AI3M-vx.x.x-TMC2208.hex - If you use TMC2208 and already reversed your connectors, use

Marlin-AI3M-vx.x.x-TMC2208_reversed.hex - If you use a newer version of the TMC2208 that doesn't require the connector to be reversed (TMC2208 "v2.0" written on the PCB, chip on the top side), please also use

Marlin-AI3M-vx.x.x-TMC2208_reversed.hex. - If you use the original stepper motor drivers, use

Marlin-AI3M-vx.x.x-stock_drivers.hex.

- Download and install Arduino IDE

- Clone or download this repo

- Browse into the Marlin folder and run

Marlin.ino - In the IDE, under

Tools -> BoardselectGenuino Mega 2560andATmega2560 - Open Marlin.ino in the Marlin directory of this repo

- Customize if needed (e.g. motor directions and type at line

559to566and line857to865inConfiguration.h) - Under

Sketch, selectExport compiled binary - Look for the .hex file in the Marlin directory (only use the

Marlin.ino.hex, not theMarlin.ino.with_bootloader.hex!)

- Flash the hex with Cura, OctoPrint or similar

- Use a tool with a terminal (OctoPrint, Pronterface, Repetier Host, ...) to send commands to your printer.

- Important Connect to the printer and send the following commands:

M502- load hard coded default valuesM500- save them to EEPROM

If you are using this on a Mega-S, those two additional commands are necessary:

M92 E384- set correct steps for the new extruderM500- save them- I highly recommend calibrating the extruder.

Calibration and other instructions have been moved to the Wiki.

If you have issues with an uneven bed, this is a great feature.

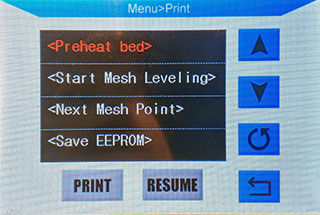

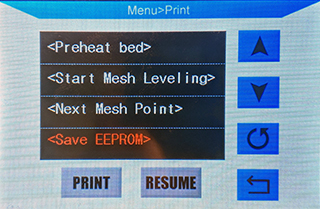

- Insert an SD card, enter the print menu.

- Enter the special menu by selecting it and pressing the round arrow:

- In this menu, the round arrow is used to execute the command you selected.

- Preheat the bed to 60°C with this entry: (if you usually print with a hotter bed, use the Anycubic menu)

- Level your preheated bed as well as you can with the four screws.

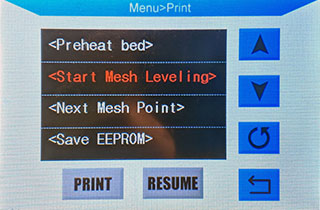

- Start the mesh leveling:

- Your nozzle will now move to the first calibration position.

- Don't adjust the bed itself with screws, only use software from here on!

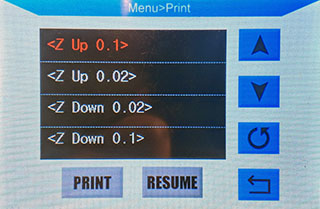

- Use a paper - I recommend using thermopaper like a receipt or baking paper

- Use the onscreen controls to lower or raise your nozzle until you feel a light resistance: (If you want to send the same command multiple times, select the item again, even though it is still marked red.)

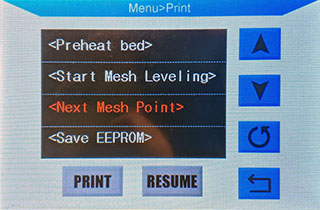

- Once finished , move to the next point:

- Repeat the last two steps until all 25 points are done.

- Your printer will beep, wait 20 seconds and then save (the printer will beep once more to confirm):

- Reboot your printer.

- To ensure your mesh gets used on every print from now on, go into your slicer settings and look for the start GCode

- Look for the Z-homing (either just

G28orG28 Z0) command and insert these two right underneath it:

M501

M420 S1

- Your printer should now correctly print first layers even on a warped bed.

- When working on the printer, installing a new hotend or nozzle or the bed warping over time, a new Mesh Leveling procedure is recommended.

G29 S1- Start MMBLG29 S2- Next Mesh point- Raising Z:

G91,G1 Z0.02,G90(one after another, not in one line) - Lowering Z:

G91,G1 Z-0.02,G90 - After seeing

okin the console, sendM500to save.

- No need to download or create a bed leveling test, simply send those commands to your printer:

G28

G26 C H200 P5 R25 Q4.2 Z4

- To adjust your filament's needed temperature, change the number of the

Hparameter - Default bed temperature is 60°C, if you need another temperature, add e.g.

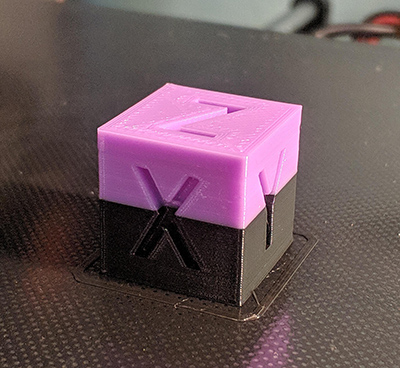

B80 Qparameter sets retraction length in mm,Zsets unretraction.- If your leveling is good, you will have a complete pattern of your mesh on your bed that you can peel off in one piece

- Don't worry if the test looks a bit messy, the important thing is just that the line width is the same all over the mesh

- Optional: Hang it up on a wall to display it as a trophy of how great your leveling skills are.

BETA: This now also works without USB printing, via SD & display.

- Send

M603 L0 U0to use manual loading & unloading. - Send

M603 L538 U555to use automatic loading & unloading- The

LandUparamters define the load and unload length in mm. The values above work well on a stock setup, if you modded your extruder, bowden tube or hotend, you might need to adjust those.

- The

- Save with

M500

- For printing via SD:

- Place

M600in your GCode at the desired layer

- Place

- For printing via USB:

- Place

M600in your GCode at the desired layer or send it via terminal - Alternatively: Use

FilamentChange Pausein the Special Menu

- Place

- The nozzle will park and your printer will beep

- For safety reasons, the printer will turn off the hotend after 10 minutes. If you see the temperature being under the target:

- SD printing: Click

CONTINUE(only once!) on the screen and wait for the hotend to heat up again. - USB printing: Send

M108and wait for the hotend to heat up again.

- SD printing: Click

- For safety reasons, the printer will turn off the hotend after 10 minutes. If you see the temperature being under the target:

- Remove the filament from the bowden tube

- Insert the new filament right up to the nozzle, just until a bit of plastic oozes out

- Remove the excess filament from the nozzle with tweezers

- For printing via SD:

- Click

CONTINUEon the screen

- Click

- For printing via USB:

- Send

M108via your USB host or useFilamentChange Resumein the Special Menu - Note for OctoPrint users: After sending

M108, enable the advanced options at the bottom of the terminal and pressFake Acknowledgement

- Send

- For printing via SD:

- Place

M600in your GCode at the desired layer

- Place

- For printing via USB:

- Place

M600in your GCode at the desired layer or send it via terminal - Alternatively: Use

FilamentChange Pausein the Special Menu

- Place

- The nozzle will park

- The printer will remove the filament right up to the extruder and beep when finished

- For safety reasons, the printer will turn off the hotend after 10 minutes. If you see the temperature being under the target:

- SD printing: Click

CONTINUE(only once!) on the screen and wait for the hotend to heat up again. - USB printing: Send

M108and wait for the hotend to heat up again.

- SD printing: Click

- For safety reasons, the printer will turn off the hotend after 10 minutes. If you see the temperature being under the target:

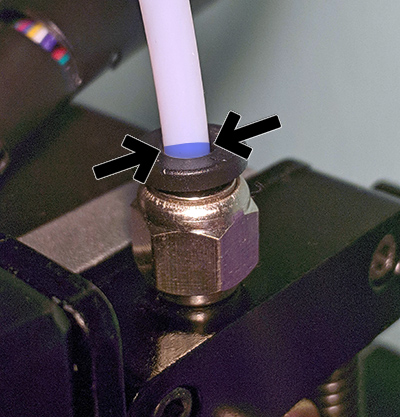

- Insert the new filament just up to the end of the bowden fitting, as shown here:

- For printing via SD:

- Click

CONTINUEon the screen

- Click

- For printing via USB:

- Send

M108via your USB host or useFilamentChange Resumein the Special Menu - Note for OctoPrint users: After sending

M108, enable the advanced options at the bottom of the terminal and pressFake Acknowledgement

- Send

- The printer will now pull in the new filament, watch out since it might ooze quite a bit from the nozzle

- Remove the excess filament from the nozzle with tweezers

Some updates require the storage to be cleared (M502), if mentioned in the update log. In those cases, before updating, send M503 and make a backup of all the lines starting with:

M92

G29

M301

M304

After flashing the new version, issue a M502 and M500. After that, enter every line you saved before and finish by saving with M500.

No worries. You can easily go back to the default firmware and restore the default settings.

- Flash the hex file from the manufacturer's website (in case it's offline, I have uploaded the stock firmwares here as well).

- After flashing, send

M502andM500. Now your machine is exactly as it came out of the box.

- Thermal runaway protection thresholds tweaked

- Manual mesh bed leveling enabled (check this link to learn more about it)

- Heatbed PID mode enabled

- TMC2208 configured in standalone mode

- Stepper orientation flipped (you don't have to flip the connectors on the board anymore)

- Linear advance unlocked (Off by default. Research, calibrate and then enable with

M900 Kx) - S-Curve Acceleration enabled

- G26 Mesh Validation enabled

- Some redundant code removed to save memory

- Minor tweaks on default jerk and acceleration

- Print statistics enabled (send

M78to read them) M600filament change feature enabled- Implemented easy resume via display

- Filament runout behaviour tweaked

- Added purge and retract

- Move nozzle to park position on runout

- Prevent false positives by adding a small delay to the sensor

- Pause and stop behaviour tweaked

- Added

M888cooldown routine for the Anycubic Ultrabase

Changes by derhopp:

- 12V capability on FAN0 (parts cooling fan) enabled

- Buzzer disabled (e.g. startup beep)

- Subdirectory support: Press the round arrow after selecting a directory

- Special menu in the SD file menu: Press the round arrow after selecting

Special menu

Not for production use. Use with caution!

Marlin 2.0 takes this popular RepRap firmware to the next level by adding support for much faster 32-bit and ARM-based boards while improving support for 8-bit AVR boards. Read about Marlin's decision to use a "Hardware Abstraction Layer" below.

This branch is for patches to the latest 2.0.x release version. Periodically this branch will form the basis for the next minor 2.0.x release.

Download earlier versions of Marlin on the Releases page.

To build Marlin 2.0 you'll need Arduino IDE 1.8.8 or newer or PlatformIO. We've posted detailed instructions on Building Marlin with Arduino and Building Marlin with PlatformIO for ReArm (which applies well to other 32-bit boards).

Marlin 2.0 introduces a layer of abstraction so that all the existing high-level code can be built for 32-bit platforms while still retaining full 8-bit AVR compatibility. Retaining AVR compatibility and a single code-base is important to us, because we want to make sure that features and patches get as much testing and attention as possible, and that all platforms always benefit from the latest improvements.

| name | processor | speed | flash | sram | logic | fpu |

|---|---|---|---|---|---|---|

| Arduino AVR | ATmega, ATTiny, etc. | 16-20MHz | 64-256k | 2-16k | 5V | no |

| Teensy++ 2.0 | AT90USB1286 | 16MHz | 128k | 8k | 5V | no |

| Due, RAMPS-FD, etc. | SAM3X8E ARM-Cortex M3 | 84MHz | 512k | 64+32k | 3.3V | no |

| Re-ARM | LPC1768 ARM-Cortex M3 | 100MHz | 512k | 32+16+16k | 3.3-5V | no |

| MKS SBASE | LPC1768 ARM-Cortex M3 | 100MHz | 512k | 32+16+16k | 3.3-5V | no |

| Azteeg X5 GT | LPC1769 ARM-Cortex M3 | 120MHz | 512k | 32+16+16k | 3.3-5V | no |

| Selena Compact | LPC1768 ARM-Cortex M3 | 100MHz | 512k | 32+16+16k | 3.3-5V | no |

| Teensy 3.5 | ARM-Cortex M4 | 120MHz | 512k | 192k | 3.3-5V | yes |

| Teensy 3.6 | ARM-Cortex M4 | 180MHz | 1M | 256k | 3.3V | yes |

| name | processor | speed | flash | sram | logic | fpu |

|---|---|---|---|---|---|---|

| STEVAL-3DP001V1 | STM32F401VE Arm-Cortex M4 | 84MHz | 512k | 64+32k | 3.3-5V | yes |

| Smoothieboard | LPC1769 ARM-Cortex M3 | 120MHz | 512k | 64k | 3.3-5V | no |

Proposed patches should be submitted as a Pull Request against the (bugfix-2.0.x) branch.

- This branch is for fixing bugs and integrating any new features for the duration of the Marlin 2.0.x life-cycle.

- Follow the Coding Standards to gain points with the maintainers.

- Please submit your questions and concerns to the Issue Queue.

The current Marlin dev team consists of:

- Scott Lahteine [@thinkyhead] - USA

- Roxanne Neufeld [@Roxy-3D] - USA

- Bob Kuhn [@Bob-the-Kuhn] - USA

- Chris Pepper [@p3p] - UK

- João Brazio [@jbrazio] - Brazil

- Erik van der Zalm [@ErikZalm] - Netherlands

Marlin is published under the GPL license because we believe in open development. The GPL comes with both rights and obligations. Whether you use Marlin firmware as the driver for your open or closed-source product, you must keep Marlin open, and you must provide your compatible Marlin source code to end users upon request. The most straightforward way to comply with the Marlin license is to make a fork of Marlin on Github, perform your modifications, and direct users to your modified fork.

While we can't prevent the use of this code in products (3D printers, CNC, etc.) that are closed source or crippled by a patent, we would prefer that you choose another firmware or, better yet, make your own.