-

-

Notifications

You must be signed in to change notification settings - Fork 365

Firmware features

Miguel Risco-Castillo edited this page Sep 7, 2023

·

4 revisions

- Universal RCT6/RET6 Ender 3 V2/S1 Support

- DWIN / DACAI / TJC / SYNWIT display support

- Improved support for Manual Mesh and CR/3D/BLTouch

- Runout icon indicator over the Extruder flow dashboard icon

- Dashboard Speed shows the current axes speed in mm/s intermittently with the speed percentage

- User configurable power lost recovery enabler

- Manual and assisted bed tramming

- Tramming Wizard for BL/3D/CRTouch versions

- Long filename support with scroll

- Axis value in dash board shows actual position of the axes, including Z leveling

- Baby Z-Stepping

- Firmware Retract

- Advanced pause feature

- Configurable park-head position (default x=240 y=220)

- Filament change support

- Filament management (load/unload/park head) in prepare menu

- Print Flow on Motion and Tune menu

- Home axis after motor disabling

- Fastest Z feed rate

- Live move for all motors but extruder

- Support for S-curve Acceleration

- Reboot printer item on control menu

- Increase extruder feed rate limit to 150 for BMG users

- Allows to invert direction of the extruder on Motion menu

- Support for BTT Smart filament sensor

- Selectable runout filament sensor active state (LOW/HIGH/MOTION)

- Editable runout distance

- Support for memory card extensions via Media Update (auto-mount) Enable/Disable menu item

- PID popup with temperature plot

- Lock screen

- Editable physical dimensions

- Mesh viewer, leveling progress and editor

- Custom pre-heat

- Enable/disable beeps sound

- View of g-code embedded thumbnail (use this guide)

- New print done screen with thumbnail support

- Two decimal positions for axis coordinates value

- New Z-Offset wizard

- New PID and MPC settings menus

- PID moves the head to the center for more accuracy

- Editable extrude minimum temperature

- Brightness settings on tune menu

- LCD brightness can dim after 5-minute timeout (configurable via M255)

- Turn off the backlight of the lcd in the tune menu

- New status line system, allows the scroll of large messages

- Home submenu with individual axis homing

- Enabled user setting for 250000/115200 baud (Creality Box compatibility)

- Head parking before recovery after power failure

- Offset icon changes to show leveling status

- Live end-stop diagnostic page

- Move bed to front after cancelling a print.

- Editable firmware retracts settings for Tune and filament settings menu

- Print Statistics page accessible from the Advanced Settings menu

- Toolbar with 5 configurable shortcuts actions.

- Support in source code of control menus for LED lights as the Neopixel

- Support up to 10 Preheat settings (needs own compile)

- Support for Linear Advance and Input Shaping in the Special Configuration repository

- TMC Trinamic driver current editor menu when it is supported (not for standalone)

- Menu item for enable/disable Adaptive Step Smoothing when it is supported

- Extrude 100 mm to Move menu for aid with extruder calibration

- Assisted manual bed tramming

- Assisted manual mesh leveling menu

- Selectable mesh points from 2x2 to 9x9

- Mesh viewer

- Persistent Z-offset

- Move Z to 0 and disable motors option

- Mesh editor for fine tuning

- Allows to set the Z height after Z home

- Safe Probe Z-Homing

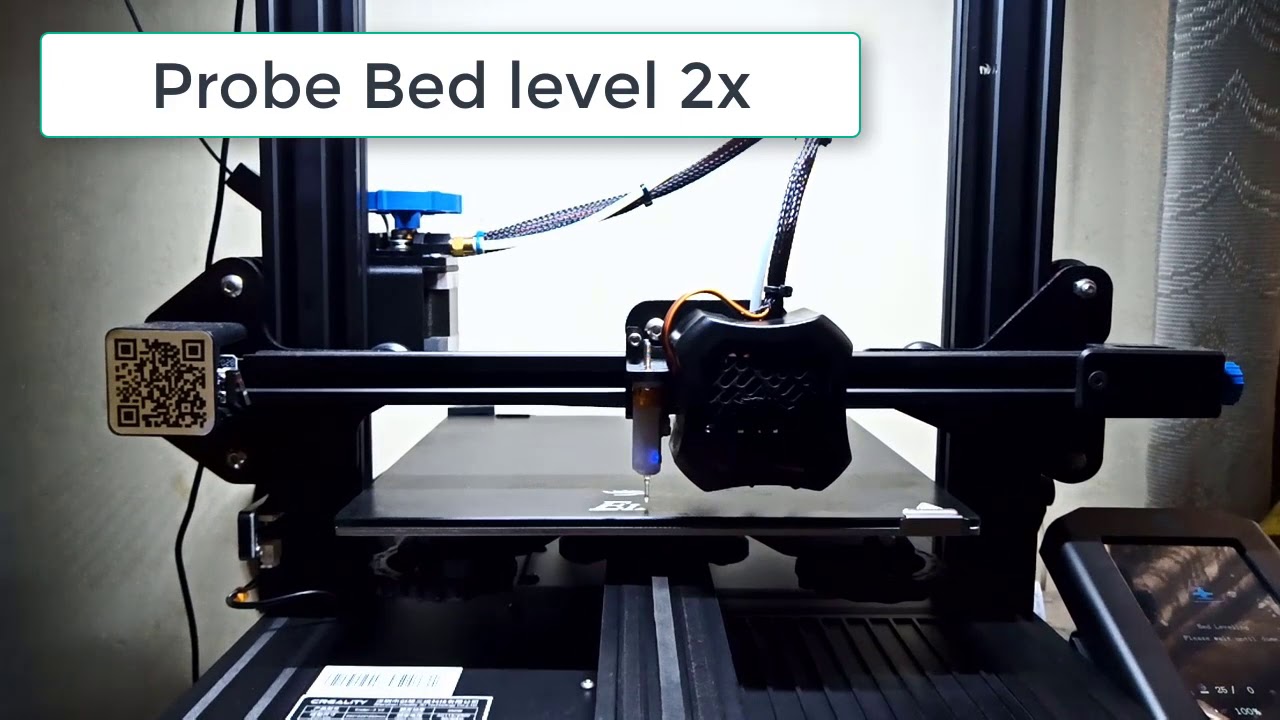

- Bed auto level

- High speed probe

- Retry bed level on error

- Mesh viewer

- Assisted tramming

- Selectable mesh points from 2x2 to 9x9

- Allows the user to cancel an auto leveling process

- Increase Max Probe Offset and Probing Margin to 60 mm

- M48 Probe Test to Probe Settings menu

- Probe Stow/Deploy in Probe Settings menu

- Option to disable HS mode for better compatibility with CRTouch

- Option to change the Z Probe feed rate

- Configurable Bed auto leveling temperature

- Mesh editor for fine tuning

- Automatic maximize leveling area

- Automatic center leveling area

- Editable multiple probing

- Leveling mesh creation progress view

- Filament Load Unload G-codes (M701/M702)

- Support for M600 filament change

- Support for G-code M117 messages

- Enable M575 change baud rate by G-code

- Extended M75 with filename support, use M75 {{ event.name }} in g-code script

- Enable ARC and 'P' parameter to specify complete circles (G2/G3)

- M155 Geometry report

- Native support of marlin display brightness and time out (M255 and M256 g-codes)

- Support to M86-M87 Hotend Idle Timeout

Support for special nonstandard custom C G-Codes

- C10 marks a G-code file as a configuration file to avoid confirm to print and print done dialogs.

- C11 En Rn Gn Bn gcode for colorize UI elements

- C29 F### B### L### R### N# T#: Mesh insets, amount of grid points and bed temperature of the mesh leveling

- C35 Launch the bed tramming wizard.

- C100 X### Y###: to sets minimum limits

- C101 X### Y### z###: sets maximum limits

- C102 X### Y###: sets bed size

- C104 U1 T###: unlocks the hotend maximum temperature to ###°C (CAUTION)

- C108: Cancels screens waiting for user simple confirmation

- C115: Shows ProUI details

- C125 X### Y### z###: sets the park position

- C250 P#: enable or disable preview screen (needs PREVIEW_MENU_ITEM)

- C412 M#: sets run-out sensor active state (M0:LOW, M1:HIGH, M2:MOTION)

- C510: locks/unlocks the screen (C510 U1 to unlock)

- C562 E#: inverts the Extruder (E1 to invert)

- C810: sets up the toolbar shortcuts

- C851 S#### [Z###] Mn: sets probe Z feed rate (S) and set Multiple probing (Mn>1) or disables it (M0), in manual mesh version, Z parameter can be used to set a manual Z-offset.

- Advanced mesh leveling editing features

- Probe offsets menu (BLTouch version)

- Customizable park-head position

- Customizable bed size and z heigh up to 999 x 999 x 999

- Launch PID for nozzle and bed with graphical feedback

- Filament run-out sensor with active state setup (LOW/HIGH)

- Filament load and unload lengths menu items in run-out menu

- Power-loss recovery enable/disable option

- LCD Brightness control

- Select Color Sub Menu

- Beep/Sound enable/disable option

- Selectable mesh point (BLTouch version)

- Media Update (auto-mount) for memory card extensions support

- Lock screen

- End-stop diagnostics

- High speed (250000 baud) serial communication

- In screen control of host printing (M73, M75-M77)

- Display messages on status line (M117)

- Color change of UI elements for visual status report (C11)

- Binary file transfer for remote firmware upgrade

- List binary (.bin) files (M20) for flash firmware support with BFT

- Arc Welder Octoprint plugin support

- EEPROM Editor Octoprint plugin support

- Host action commands for filament runout

- Emergency Parser active

- Advanced OK

Octoprint bed visualizer support

- Extended Display library

- Enhanced status messages

- MPC/PID auto tune progress on display with plot

- Leveling progress on display

- Boot screen for M997

- Transparent icons for better color theme adaptability (depends on display unit)

- LCD brightness can dim after 5-minute timeout (configurable via M255)

- G-code thumbnail preview

- Print done screen with thumbnail preview

A lot of additions and fixes from Bugfix development branch

- Creality CV laser module support with automatic file type detection

- Creality Cloud Support

- Menu item for enable/disable file list sorting

- Several additional enableable menu items via #defines RUNOUT_TUNE_ITEM, PLR_TUNE_ITEM, JD_TUNE_ITEM, ADVK_TUNE_ITEM

- Linear Advance (LA) support

- Input Shaping (IS) support

- TMC Trinamic driver current editor

This Wiki and the included images were created under the Creative Commons License CC BY-NC-SA

Get the latest firmware here: https://github.com/mriscoc/Ender3V2S1/releases/latest