-

Notifications

You must be signed in to change notification settings - Fork 0

05.6_Converge

== Electronic group ==

Qiuyang Zhou : choose parts, stay on schedule.

Gabriella Levine : hack electrics / electronics

Logan Williams : optimize circuits / consumption, response time. Choose next generation of parts.

== Mechanical group ==

Roberto Melendez : define good hull shape, buoyancy, weight. Define the weak points, torque required to bend the hull.

Sebastian Muellauer : design the actuation system. Choose hull materials and processes.

Sebastin Neitsch : connect the electric and mechanical group. Work on data feedback from the embed Xbee.

Cesar Harada : Design the mechanics of the hull

== Oil group ==

Francois de la Taste : define test matrix for different oil cleaning equipment. Order test materials, build experimental setups.

Electric

From a standard 12V hacked cordless drill =>

- Know your battery. Define the specs of the batt. (V, A, Peak, Duty cycle ...)

- Know your motor. RPM and Torque f V, A ...

We need to know our current motor to project for future part order (more efficient motors / batteries)

Electronic

- Establish good 2 way communication between "base" and "embed" Xbees.

- Control speed, direction and torque of 2 motors. Reduce response time to minimum.

- Control the approximate position of the motor (feedback).

- Log movement data so we can replicate experiments.

- Either use keyboard / hacked RC command to control the Xbee sailing robot.

Mechanic

- choose a hull design that is modular and that we can adjust (weight, shape, motors, payload).

- Mechanical system should be robust and have a short response time using the motors chosen by the electric team for better maneuverability and minimum response delay.

Oil

- Define the test matrix that is required, and design the tests (environment, material, process, etc.)

Electrical

- Design and get insulative tube for power cables and sensor signal cables

- Design the layout of the electronics components and find the appropriate water proof box to encapsulate them.

- Get the control code running

Mechanical

- Finishing test model for cable actuation

- Order the appropriate lead screw and nut for actuation

- Get longer Bowden cables (> 2m)

- Mechanical design for winch box

- reinforce the sail

- design the size and weight of the keel and the ballast.

We took apart an inexpensive cordless drill to find a high amperage (10A, up to 80A stalled) DC motor.

| Component | Info | Picture (click to open) |

|---|---|---|

| V1/ microcontroller--> high amperage motor (hacking a cordless drill) |  |

|

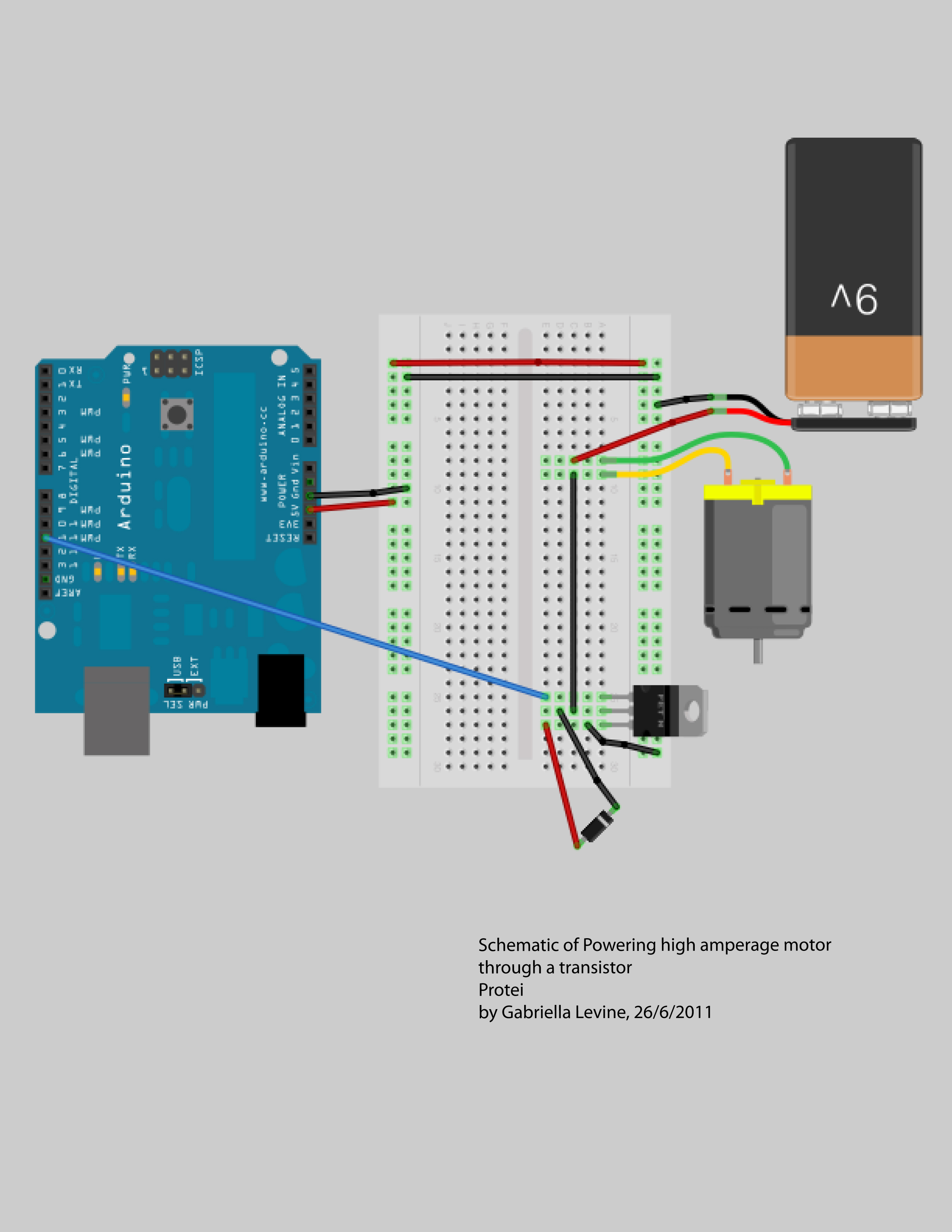

| Schematic (of motor driving, since outdated) | A simple schematic for controlling a high amperage load through Arduino by using an external power source powered through a TIP120 transistor (made with Fritzing)-->(update - 6.28.2011 - use the MOSFET transistor that comes attached to the motor of the drill, configured identically to the TIP 120 in this circuit diagram) |  |

| Arduino drawing (made with Fritzing): | diagram with a microcontroller (Arduino, here; made with Fritzing) - replace the 9V battery with whatever battery pack we will be using. This is the circuit used to power the drill. |  |

| Code | Is available from the Protei git repository | |

| Xbee-box wiring | Has been made with an Ethernet plug --> (RJ45 Pin 1 - Orange - XBee pin 1 (Vcc)) (RJ45 Pin 2 - Green - Xbee pin 2 (Dout)) (RJ45 Pin 3 - Blue) (Xbee pin 3 (Din)) (RJ45 Pin 4 - Brown - Xbee pin 10 (GND)) |

|

Control system schematic

Cable layout

- Configuration of the two XBee.

We use a Coordinator----End device communication pattern, which means one of the XBee is configured as coordinator of the wireless network and the other is configured as the end device.

For this simple communication pattern, the above configuration is enough.

2.Xbee Range Tests: reliable tx/rx <150 m outdoors, <80m indoors

3.Global electronic layout (original Illustrator source file in attachment):

Linear Actuators:

Winch:

Download Xbee_Motor.pde

Selection of control platform (Hardware+software) There are plenty of UAV controller platforms in progress, both in open hardware platform and private commercial platform. What is the best one? Here we are not going to make a comparison of all the platforms, thus what we select maybe is not the "best" one. But we will have a direction where we are aiming for.

Some characteristics which must be contained in the platform:

- Easy to use!

- Configurable operation parameters, and should be easy to configure (friendly GUI). For example: how many inputs & outputs, parameter range.

- Opensource

- good to have some design standard.

- Have supporting software, like simulation software, debugging software....

- should be Well-known.

- enough computation power.

- Hardware can be upgraded.

- ..........

What we are using now is Leaflabs Maple v5 + ArdoPilot Mega.

Now, we are using Leaflabs Maple V5

Advantage:

- Easy to set-up, fast prototype.

- Huge computation power, don't have to plan the code very much.

- Enough inputs&outputs.

- Cheap (in case of broken)

Later (late July and August), we shift the platform to ArduPilot Mega

Advantages: Most important: the boat share the same position data with the airplane, such as head,roll,pitch, yaw, x-y-z speed, etc. So what can be reused is the hardware platform plus the library source. What has to be re-define is the control and guidance strategy.

-

Well designed, time proven hardware structure. Pins are arranged nicely. well designed sensor board, compact connection. Dual Atmega processors on-board, single processor fail-safe system.

-

Well designed, time proven software firmware. Well designed firmware structure.

Friendly user configurable interface, configurable system. Well designed test running mode. -

Enough external software support, including Mission plan system and Ground control system. HIL simulation support.

-

Well defined C++ classes, easy to use. For example, to use GPS, you simply call GPS.update(). Then all the data are available.

-

Well known system, has plenty of users , supporters, developers. complies with the

spirits of Protei. -

Can have good collaboration with ArduPilot suppliers.

-

Support Hardware upgrade.

-

Computation power: It is enough. from the embedded control system perspective, if we consider airplane as the hard deadline system, then the same hardware could apply for the airplane and autonomous boat. Because the boat can be classified as soft hard deadline system. But we need to plan the code nicely.

-

we have to customize the ardupilot's firmware to fit our design, which do take some time, but this is definitely worthwhile. What I can expect is we do 10 ~20% of customization of ardupilot firmware, then we have a well functioned system.

So, the development time line for our firmware is :

From Leaflabs Maple V5 TO ArduPilot Mega.

See Protei-6.0